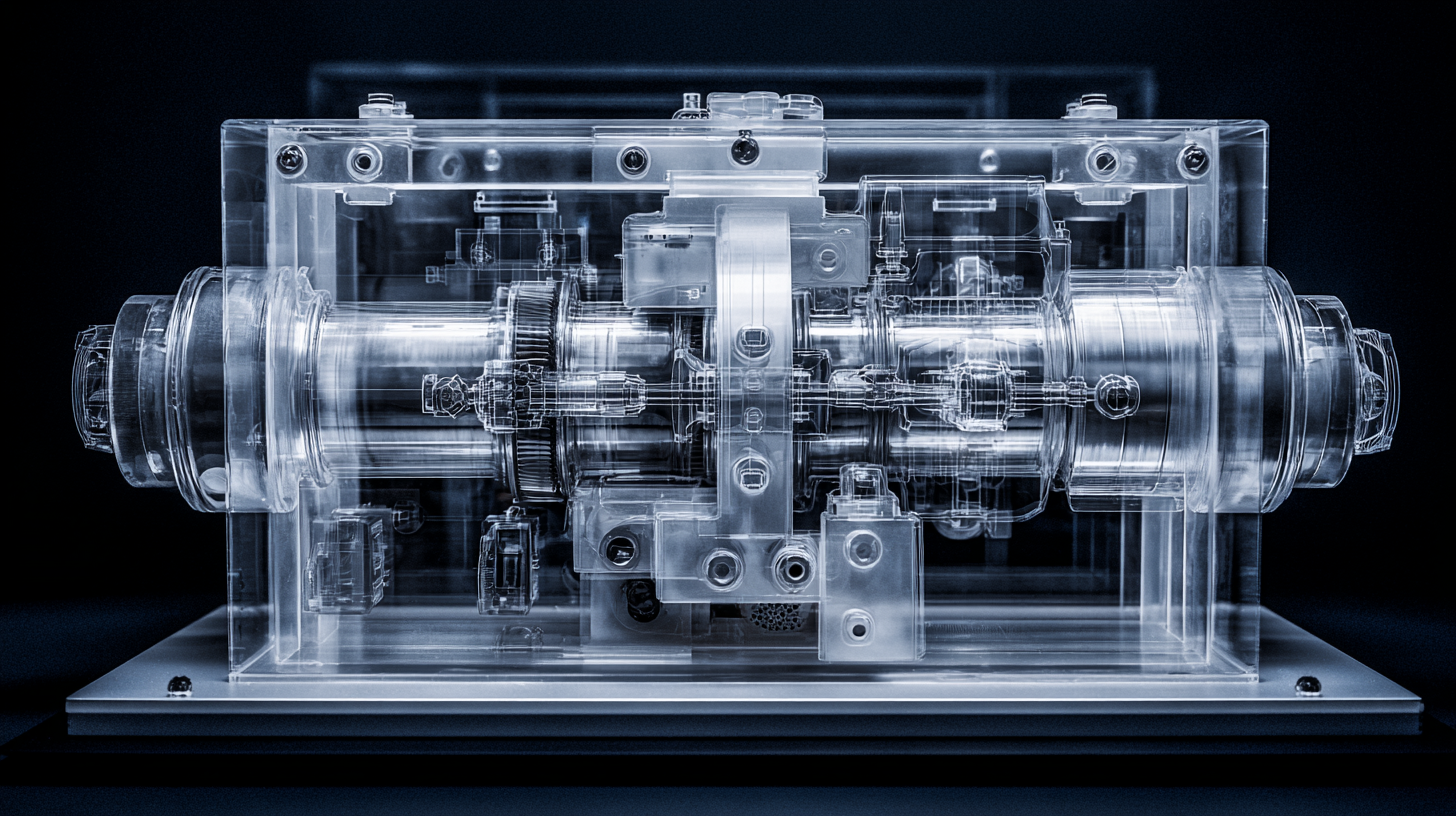

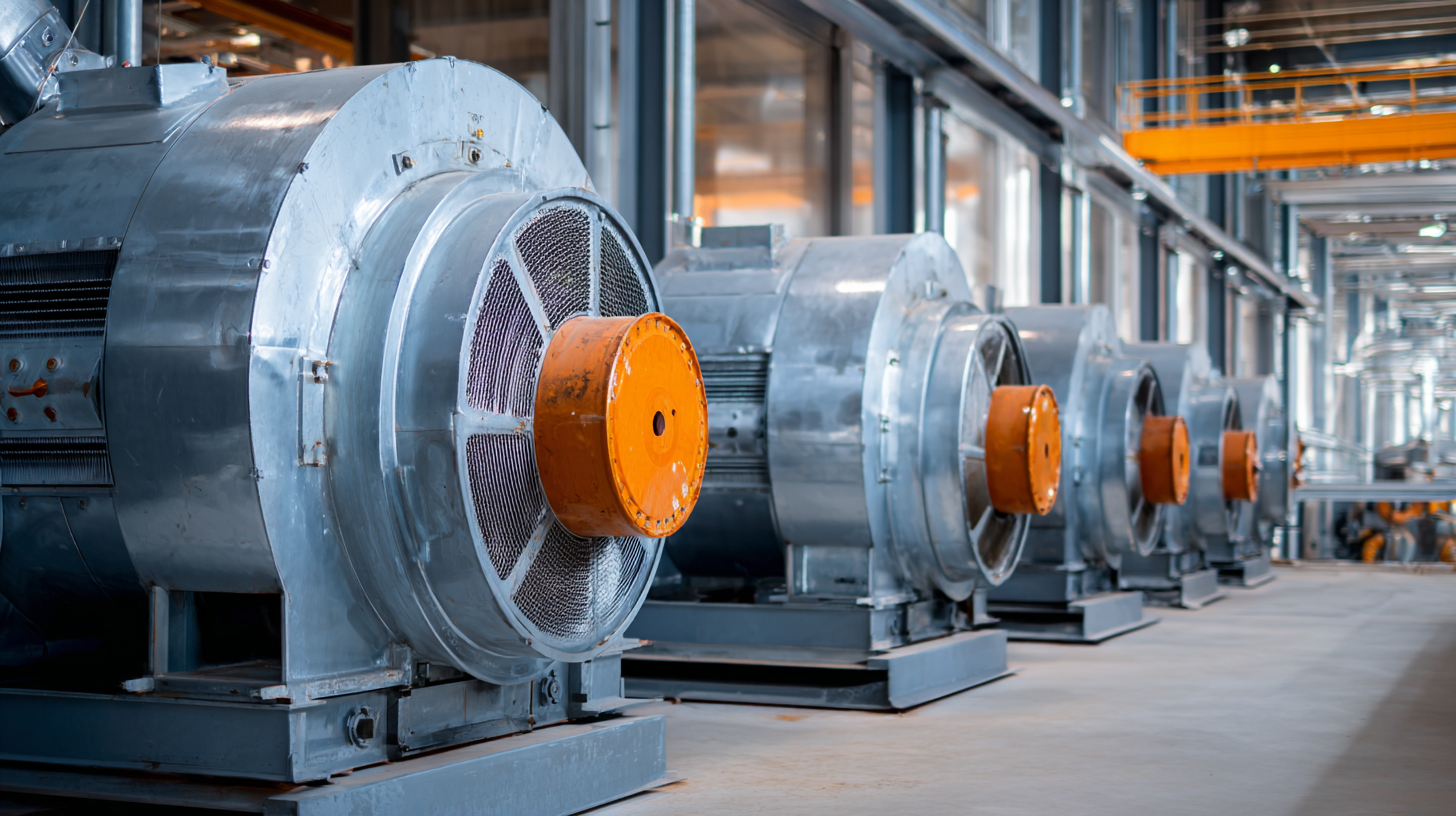

In the ever-evolving landscape of industrial technology, regenerative blowers have emerged as a pivotal component in enhancing operational efficiency and sustainability. Dr. Emily Thompson, a renowned expert in fluid dynamics and regenerative systems, emphasizes the importance of these devices by stating, "The adoption of advanced regenerative blower technology not only optimizes energy consumption but also reduces environmental impact, making it a smart choice for modern industries." As we approach 2025, the top contenders in the regenerative blower market are set to redefine performance benchmarks.

This article delves into the top 10 regenerative blowers that are leading the charge in efficiency and innovation. By harnessing cutting-edge technological advancements, these systems are designed to provide reliable air movement while minimizing energy losses. In an era where operational efficiency is paramount, understanding the capabilities and features of these blowers becomes essential for businesses looking to enhance their productivity while remaining environmentally conscious. Join us as we explore these state-of-the-art solutions that are not only transforming the blower industry but also setting new standards for what can be achieved in industrial applications.

The regenerative blower market is poised for significant growth, reflecting a broader trend in industrial applications. According to recent market research, the global regenerative blowers market is projected to experience robust expansion, leveraging advancements in technology to enhance efficiency and performance. These developments are crucial as industries increasingly seek reliable and energy-efficient machinery to optimize operations.

With a compound annual growth rate (CAGR) of 12.2%, the market for regenerative blowers is expected to surge from an estimated $150 billion in 2025 to approximately $336.2 billion by 2032. This growth is driven by the rising demand for innovative air management solutions across various sectors, including manufacturing, food processing, and wastewater treatment, as industries prioritize improved energy consumption and operational effectiveness.

The integration of smart technology into regenerative blowers is set to revolutionize their functionality, enabling predictive maintenance, improved user interfaces, and enhanced control systems. These advancements not only promise to boost operational efficiency but also align with sustainability initiatives, highlighting the critical role that regenerative blowers will play in the future of industrial applications.

This chart illustrates the projected efficiency improvements of regenerative blowers across different industrial applications by 2025. The data reflects advancements in technology that enhance performance in various sectors.

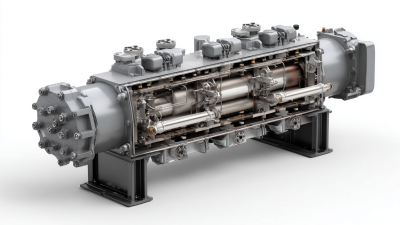

Regenerative blowers are revolutionizing various industries by enhancing efficiency through advanced technologies. With the global industrial fans and blowers market expected to exceed USD 10.6 billion by 2024 and grow at a CAGR of 4.3% from 2025 to 2034, the demand for high-performance regenerative blowers is set to rise significantly. These blowers offer optimal solutions for applications such as biogas digesters, where their ability to handle corrosive and highly combustible gases is crucial.

Key features to examine when considering regenerative blowers include energy consumption efficiency, noise reduction capabilities, and maintenance requirements. The adoption of these advanced technologies not only optimizes operational processes but also contributes to reduced environmental impact. By incorporating innovative designs that enhance airflow and minimize energy loss, regenerative blowers are increasingly being recognized as indispensable tools in various sectors, from wastewater treatment to food processing. As the industry continues to evolve, the integration of smarter technologies within regenerative blowers is likely to further boost performance and sustainability.

| Model | Max Airflow (CFM) | Pressure (in H2O) | Efficiency Rating | Noise Level (dB) | Weight (lbs) |

|---|---|---|---|---|---|

| Model A | 800 | 15 | 90% | 75 | 150 |

| Model B | 950 | 20 | 92% | 70 | 160 |

| Model C | 780 | 25 | 88% | 80 | 145 |

| Model D | 850 | 18 | 91% | 72 | 155 |

| Model E | 900 | 22 | 93% | 68 | 165 |

As the demand for energy-efficient solutions continues to grow, regenerative blowers have emerged as vital components in various industrial applications. In 2025, the top models in this category are distinguished not only by their design but by their impressive performance metrics. A detailed comparison of energy consumption and output efficiency reveals significant variations among leading regenerative blowers. For instance, some models utilize advanced aerodynamics to minimize energy loss, allowing them to deliver higher airflow rates while consuming less power.

Furthermore, when evaluating the output efficiency, it’s crucial to consider factors such as pressure generation and operational stability. The latest regenerative blowers employ cutting-edge technology, including variable speed drives and enhanced motor designs, which enable them to adjust performance dynamically based on the specific needs of the application. Consequently, this adaptability results in superior energy management and reduced operational costs. By prioritizing both energy consumption and output efficiency, users can make informed decisions to maximize their investment in regeneration technology.

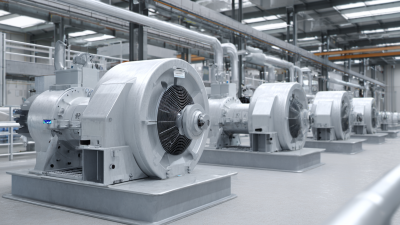

The advancements in regenerative blowers are not just about improved efficiency but also about significant cost savings in operations. Recent case studies indicate that companies utilizing modern blower solutions witness measurable reductions in energy consumption, leading to lower operational expenses. By integrating advanced technologies such as AI and automation, these blowers can optimize airflow and minimize waste, which becomes increasingly crucial as industries face rising energy costs and environmental pressures.

Moreover, the shift towards smarter technologies in industrial applications resonates with broader trends in operational management. For instance, the deployment of data analytics in facilities management highlights how intelligent systems can enhance not only efficiency but also overall productivity. Companies that adapt to these innovations, particularly in using regenerative blowers, position themselves favorably in an evolving market landscape. As the operational focus on cost savings continues to intensify, leveraging these advanced blower solutions could prove vital for sustained competitiveness and profitability in 2025 and beyond.

As we look ahead to 2025, the landscape of regenerative blower technology is set to undergo significant innovations that will enhance performance and efficiency. The evolution of materials and design methodologies will lead to lighter, more robust blowers that can operate at higher speeds while minimizing energy consumption. Advancements in software will also play a critical role, with smarter control systems enabling more precise adjustments to airflow and pressure, thereby optimizing productivity across various applications.

Tips: When considering an upgrade to your blower system, prioritize options with advanced features like variable frequency drives (VFDs). These allow for better energy management by aligning blower speeds with system requirements, ultimately reducing waste and lowering operating costs.

Moreover, the integration of IoT technology will enable real-time monitoring and predictive maintenance, giving users the ability to assess performance metrics remotely. This will lead to not only reduced downtime but also a significant increase in operational reliability. The combination of these innovations will redefine how industries utilize regenerative blowers, ensuring they remain a vital component in efficient industrial processes.

Tips: Ensure your facility is equipped with the latest monitoring tools to track the efficiency of your regenerative blowers. Regularly analyze performance data to anticipate wear and avoid unplanned outages that could disrupt operations.