The advancements in industrial equipment continue to shape various sectors, and the ring blower market is no exception. According to a recent report by MarketsandMarkets, the global ring blower market is projected to reach USD 1.2 billion by 2025, growing at a CAGR of 6.3% from 2020. This growth is driven by the increasing demand for efficient air supply and vacuum generation across various applications including wastewater treatment, pneumatic conveying, and chemical processes. As industries strive for enhanced operational efficiency and reduced energy consumption, the role of ring blowers in optimizing performance has never been more critical.

In 2025, key trends in ring blowers will revolve around technological enhancements and sustainable practices. The introduction of energy-efficient models that minimize noise and maximize airflow rate is expected to lead the charge in new product developments. Furthermore, innovations such as smart monitoring systems and IoT integration are anticipated to enhance the functionality and user experience of ring blowers. This presents a vital opportunity for manufacturers to meet the evolving demands of modern industry while contributing to sustainability goals. Understanding these trends, features, and benefits is essential for businesses looking to leverage ring blowers effectively in their operations.

The ring blower industry is set to witness significant advancements in 2025, particularly in technology and efficiency improvements. According to a recent report from ResearchAndMarkets, the global blowers market is expected to grow at a CAGR of 5.2% from 2023 to 2028, driven largely by innovations such as smart monitoring systems and enhanced energy efficiency features. These innovations not only reduce operational costs but also minimize environmental impact, aligning with the global push towards sustainability in industrial processes.

One of the most notable trends in ring blower technology is the integration of IoT (Internet of Things) capabilities. This advancement allows for real-time monitoring and predictive maintenance, significantly enhancing performance and lifespan. By employing data analytics, companies can optimize their operations, identifying potential issues before they escalate. Further, the introduction of variable speed drives is revolutionizing the market by enabling blowers to adjust their output in response to fluctuating demand, which can lead to energy savings of up to 30%, as highlighted in a study by the Department of Energy. Such features demonstrate the industry's commitment to improving operational efficiency while adhering to stringent regulatory standards.

This bar chart illustrates the key features and benefits of ring blowers as anticipated in 2025. Trends such as energy efficiency, reduced noise levels, and advanced materials are becoming essential in the ring blower technology landscape.

As we move into 2025, the ring blower market is set to embrace a variety of innovative features that enhance performance and efficiency. One of the key aspects to consider is the energy efficiency of these blowers. According to a recent market analysis by Research and Markets, energy-efficient models can reduce operational costs by up to 30%, making them an attractive option for industries focused on sustainability and cost reduction. Manufacturers have begun to integrate advanced motor technologies and control systems that optimize energy consumption while maintaining high airflow rates.

Another notable trend is the emphasis on noise reduction in ring blowers. The demand for quieter operational environments continues to rise, particularly in urban settings and workplaces. Data from industry reports indicate that blowers featuring noise-dampening technologies can achieve sound levels as low as 70 dB, which is significant for applications in light manufacturing and food processing where noise pollution can be a concern. Moreover, the incorporation of vibration-dampening mounts further enhances operational stability, reducing wear and prolonging equipment life.

Lastly, the versatility of modern ring blowers is a critical feature to monitor. In 2025, we can expect to see more multi-functional blowers capable of handling various applications from aeration to pneumatic conveying. The increasing adaptability of these systems is underpinned by advances in materials and design, allowing for customization options that cater to specific industry requirements. Reports show that the overall market for versatile fluid management solutions is expected to grow significantly, driven by the need for efficient and flexible equipment in highly competitive sectors.

Upgrading to advanced ring blowers offers numerous advantages that can significantly enhance operational efficiency across various industries. As processes require more energy-efficient solutions, modern ring blowers have evolved to provide superior performance. According to a recent market analysis, the global ring blower market is expected to grow at a CAGR of 5.2% from 2023 to 2028, indicating a rising demand for more advanced systems that address both energy consumption and operational reliability.

One of the key benefits of these upgraded systems is their higher efficiency. Advanced ring blowers are designed with optimized airflow characteristics that reduce energy usage while maintaining performance. Reports indicate that companies can achieve energy savings of up to 30% compared to older models, resulting in significant cost reductions over time. Additionally, many new blowers come equipped with smart technology that allows for real-time monitoring and predictive maintenance, which not only minimizes downtime but also extends the lifecycle of the equipment.

Furthermore, the quieter operation of advanced ring blowers improves the working environment for employees. Traditional systems often produce excessive noise, which can contribute to workplace fatigue. Newer models utilize noise-dampening technology that can lower decibel levels by as much as 10 dB, creating a more pleasant atmosphere while complying with workplace safety standards. In summary, upgrading to advanced ring blowers not only enhances energy efficiency and performance but also contributes to a healthier work environment and operational cost savings.

| Feature | Benefit | Trend | Comparison (2023 vs 2025) |

|---|---|---|---|

| Noise Reduction Technology | Quieter operation, improving workplace conditions | Growing demand for low-noise equipment | Decrease in decibel levels by 20% |

| Energy Efficiency | Lower energy consumption reduces operational costs | Shift towards sustainable operations | Energy savings of up to 30% |

| Smart Technology Integration | Real-time monitoring and diagnostics for performance | Increase in automation and IoT in machinery | Adoption of smart technologies up by 50% |

| Compact Design | Space-saving solutions for smaller facilities | Increasing need for optimizing production space | Sales of compact models up by 40% |

| Durability Improvements | Longer lifespan and reduced maintenance costs | Demand for reliable and robust industrial equipment | Maintenance frequency reduced by 15% |

As industries increasingly focus on sustainability and reducing operational costs, energy efficiency has become a pivotal consideration in the design of ring blowers. Recent reports indicate that advancements in materials and engineering have led to the development of blowers that consume up to 30% less energy than their predecessors. This shift is driven by the need for manufacturers to meet stringent energy regulations while optimizing performance. Innovations such as improved aerodynamics and variable speed drives have demonstrated significant potential in enhancing efficiency, thus leading to lower energy consumption and reduced environmental impact.

Tips: When selecting a ring blower, it's essential to evaluate its energy rating alongside performance specifications. This will help ensure that you invest in a model that provides optimal efficiency while meeting your operational demands.

The adoption of smarter technologies in ring blower designs is also contributing to energy efficiency. Incorporating advanced monitoring and control systems allows users to track real-time energy usage and adjust operations for maximum efficiency. Reports suggest that companies implementing these technologies can achieve energy savings of up to 20%. The trend towards integrating IoT-enabled features in blower systems not only optimizes energy efficiency but also enhances the overall operational effectiveness across various industries.

Tips: Regular maintenance and monitoring are crucial in sustaining energy efficiency gains. Establishing a routine check can prevent inefficiencies from developing over time and ensure that your equipment runs at its best.

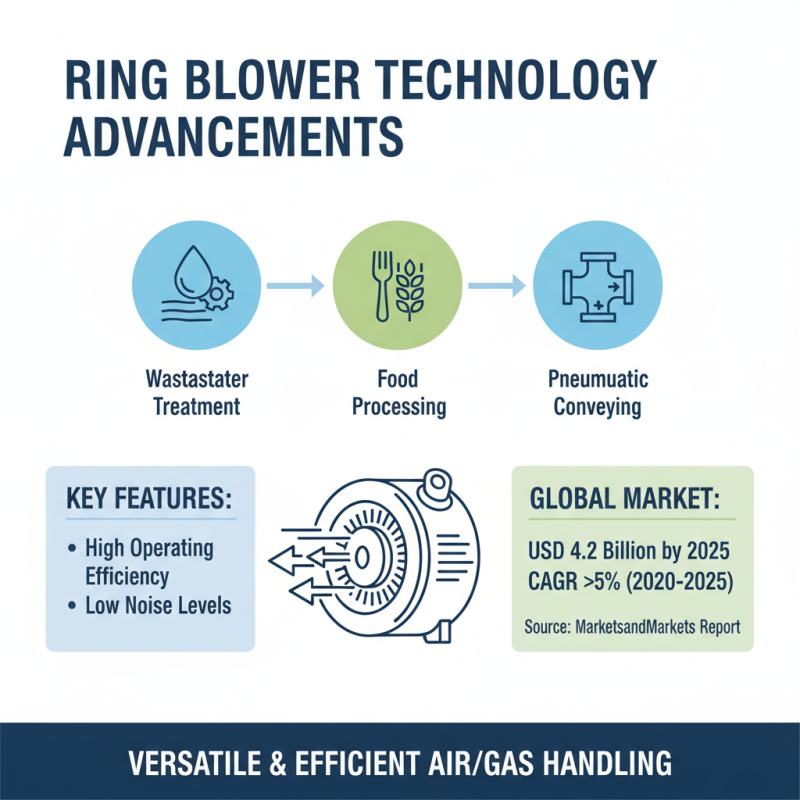

The advancements in ring blower technology have significant implications across various industries, reflecting their versatility and efficiency. Ring blowers, known for their high operating efficiency and low noise levels, are increasingly being utilized in sectors such as wastewater treatment, food processing, and pneumatic conveying systems. According to a report by MarketsandMarkets, the global market for positive displacement blowers, which includes ring blowers, is projected to reach USD 4.2 billion by 2025, growing at a CAGR of over 5%. This growth can be attributed to the rising need for efficient air and gas handling systems in various industrial applications.

In the wastewater treatment sector, ring blowers are crucial for aeration processes, improving oxygen transfer efficiency. The use of ring blowers helps achieve energy savings of up to 30% compared to traditional blower systems, a significant advantage given that energy costs can account for over 60% of the operational expenses in such facilities. Additionally, the food processing industry benefits from ring blowers in bulk material movement and packing applications, where reliability and hygiene are paramount. The ability to maintain consistent airflow while minimizing contamination risks makes these systems increasingly popular among manufacturers looking to enhance productivity and ensure product quality. As industries continue to evolve and seek more efficient solutions, ring blowers are poised to play a pivotal role in meeting these demands.