The demand for efficient performance in various industries has led to innovative developments in technologies like the Side Channel Blower. As we approach 2026, significant advancements are expected in this field. These innovations aim to enhance energy efficiency, reduce noise levels, and improve durability, offering more cost-effective solutions for businesses.

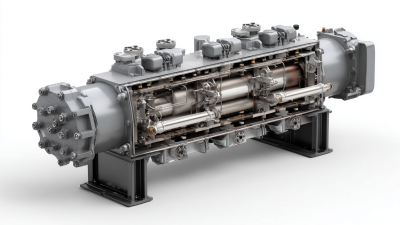

Side Channel Blowers are essential components in many applications, including vacuum systems and pneumatic conveying. Their ability to provide consistent airflow makes them valuable in diverse sectors. However, some outdated designs remain in use, which can hinder overall performance. This gap presents opportunities for innovation.

Looking ahead, the industry is witnessing a shift toward smarter designs and materials. New features may include better sound insulation and advanced control systems. These improvements could result in a more user-friendly experience. Yet, while innovation is promising, it also raises questions about balancing cost with performance. As we explore these upcoming advancements, careful consideration is needed to ensure that technology remains accessible and effective for all.

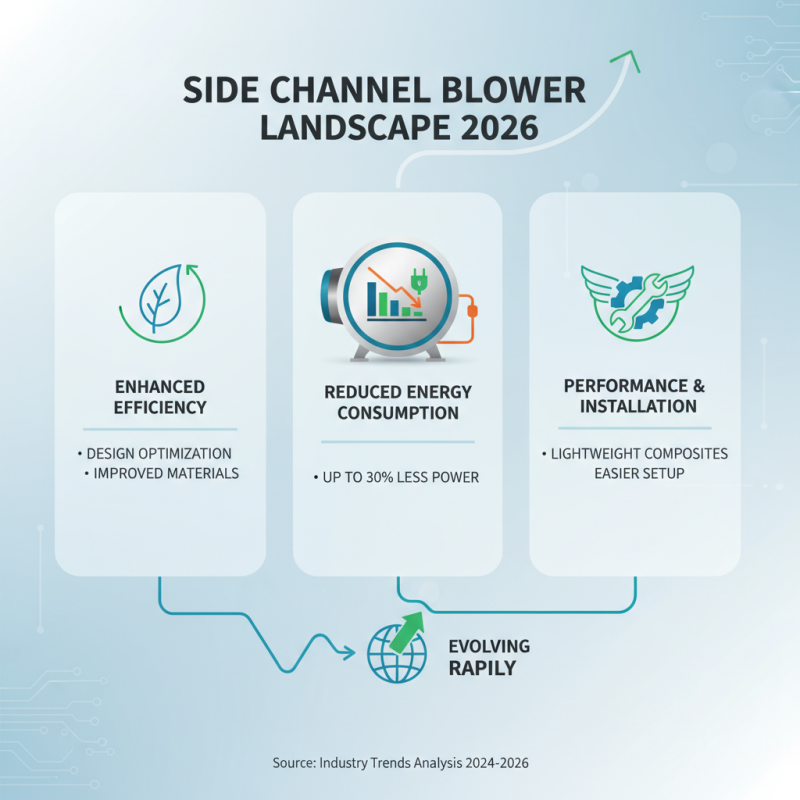

As we look toward 2026, the side channel blower landscape is evolving rapidly. Emerging technologies focus on enhancing efficiency and performance. Innovations are centered around design optimization and improved materials. These advancements promise to reduce energy consumption significantly. Manufacturers are experimenting with lightweight composites, making blowers more efficient and easier to install.

One notable trend is the integration of smart technology. Smart blowers can monitor performance in real-time. Sensors collect data to adjust operation based on demand. This can lead to incredible energy savings but raises concerns about reliability and maintenance. Will these new systems require more frequent repairs?

Another area for exploration is noise reduction. Side channel blowers often create significant operational noise. New designs utilizing advanced acoustics aim to minimize sound levels. However, this may come at the cost of airflow efficiency. Stakeholders need to balance performance with user comfort. The future of side channel blowers relies on embracing these challenges. The goal is to create solutions that not only work better but also address the needs of a changing market.

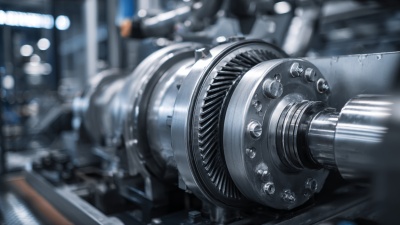

The landscape of side channel blowers is evolving rapidly. Innovations are emerging to address efficiency demands. Manufacturers aim to improve energy consumption and performance metrics. Recent advancements in materials and design are showing promise. Lightweight composites are gaining attention for reducing overall weight. This innovation may lead to higher efficiency in performance.

Moreover, smart technology integration is reshaping the operational framework of side channel blowers. Real-time monitoring can optimize performance. However, there are challenges in implementing such systems. Compatibility with existing setups is often questioned. The complexity of integration can hinder adoption rates.

Aerodynamic design improvements are key to enhancing performance. Streamlined shapes reduce turbulence and energy loss. However, achieving optimal designs often requires extensive testing. Balancing performance with manufacturability is a daunting task. The pursuit of efficiency continues, but obstacles remain in the way of these innovations.

In 2026, innovations in side channel blowers focus heavily on energy efficiency. New models showcase advanced designs, reducing power consumption significantly. By optimizing airflow paths, these systems enhance performance while using less energy. Users can expect quieter operation too, thanks to improved sound-dampening technologies.

Tips: Consider the size of your application. A unit that is too large can waste energy. Smaller models may offer sufficient airflow at lower operational costs. Don’t forget to look into variable speed options. They adapt to your needs, saving even more energy.

Efforts towards sustainability are visible in improved materials as well. Light but durable components help reduce the overall weight. This change is beneficial for performance and transportation. Yet, there are challenges. Some users may find initial investments higher. Reflect on the long-term savings versus upfront costs. Balancing these can lead to smarter decisions in the long run.

| Model | Power (kW) | Max Flow Rate (m³/h) | Efficiency (%) | Noise Level (dB) |

|---|---|---|---|---|

| Model A | 15 | 750 | 85 | 65 |

| Model B | 20 | 950 | 90 | 68 |

| Model C | 25 | 1200 | 92 | 70 |

| Model D | 30 | 1500 | 88 | 72 |

| Model E | 35 | 1700 | 95 | 71 |

The 2026 landscape of side channel blowers is set to embrace smart technologies, enhancing efficiency. These innovations will integrate advanced sensors and IoT capabilities. Imagine blowers that adjust performance based on real-time data. Efficiency could significantly improve, but challenges remain.

Smart technologies may introduce complexity. For instance, software updates could lead to system disruptions. Moreover, relying on tech might reduce human oversight. A balance must be struck between automation and manual control.

Users can expect intuitive interfaces. This will allow easier monitoring and adjustments. However, there could be a learning curve. Workers may need training to maximize benefits. As these technologies become standard, adaptability will be key to effective performance.

The side channel blower industry is evolving rapidly. Innovations are focusing on improving efficiency and reducing environmental impact. These advancements aim to minimize energy consumption while maximizing performance. Manufacturers are exploring new materials and designs that enhance airflow while reducing noise pollution. This shift is not just a trend; it reflects a broader commitment to sustainability.

Tips: Always look for efficiency ratings. Higher performance often correlates with lower energy use.

Recycling and reusing components in manufacturing can significantly lower waste. Adopting sustainable practices is becoming essential. This includes using eco-friendly lubricants and minimizing packaging waste. Each small change can contribute to a healthier environment.

Tips: Consider local sourcing for parts. It often reduces transportation costs and carbon footprints.

Monitoring and optimizing operational conditions is critical. Regular maintenance can prevent inefficiencies and emissions. Despite advancements, users should remain vigilant about their systems' performance. Reflecting on the impact of these blowers on air quality is also important.