Centrifugal Air Fans play a crucial role in a variety of industrial applications, serving as essential components in ventilation systems, cooling processes, and material handling. According to a recent market analysis report by Research and Markets, the global centrifugal fan market is expected to reach USD 5.2 billion by 2027, driven by the increasing demand for effective airflow management in industries such as manufacturing, automotive, and HVAC.

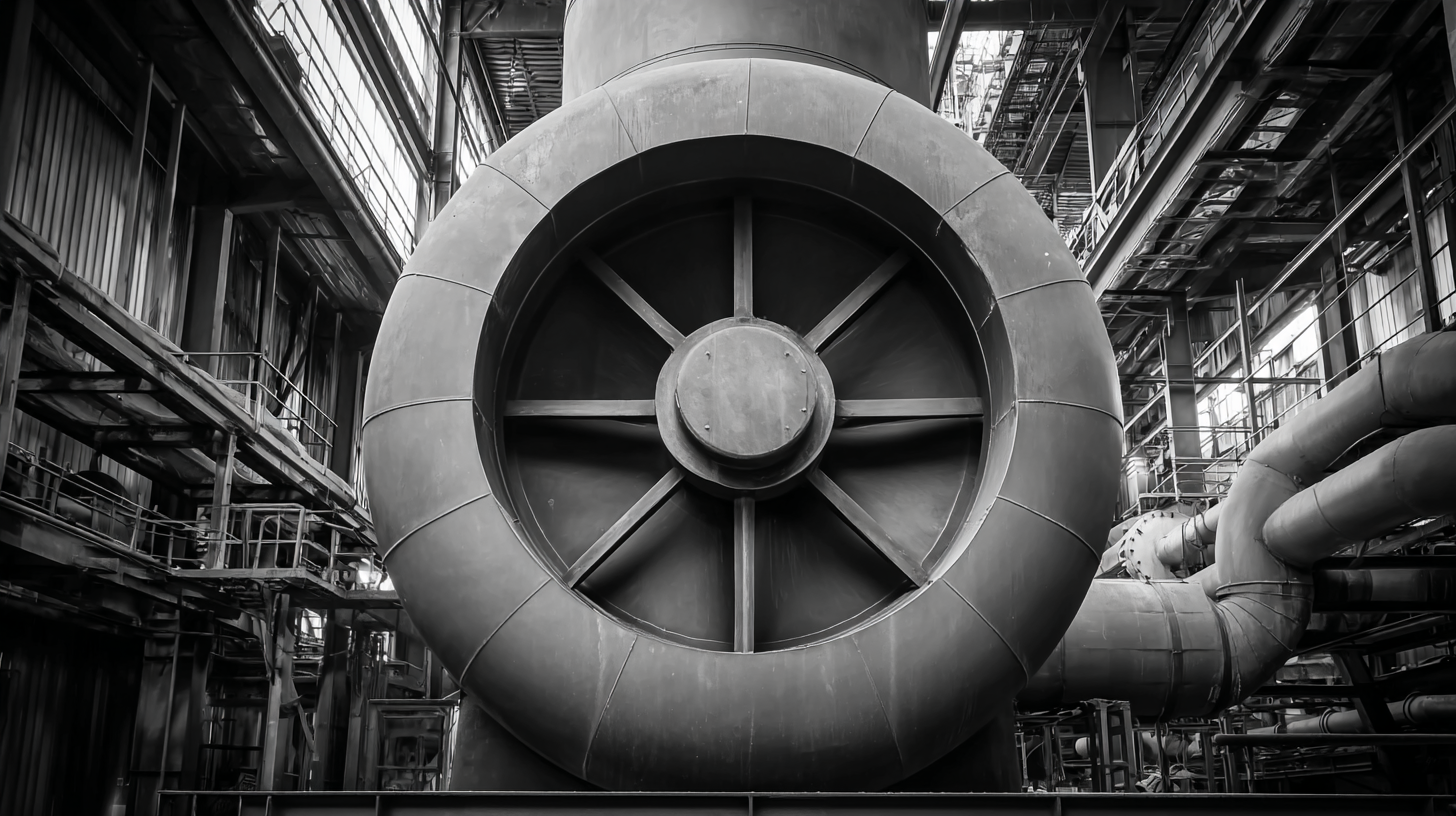

These fans operate on the principle of converting rotational kinetic energy into the flow energy of air, providing superior pressure capabilities compared to axial fans. Their ability to handle high volumes of air against significant resistance makes them invaluable in scenarios where air distribution and exhaust efficiency are critical. As industries strive for enhanced energy efficiency and operational performance, understanding the benefits of Centrifugal Air Fans becomes imperative for optimizing air management systems and ensuring compliance with environmental regulations.

Centrifugal Air Fans play a crucial role in a variety of industrial applications, serving as essential components in ventilation systems, cooling processes, and material handling. According to a recent market analysis report by Research and Markets, the global centrifugal fan market is expected to reach USD 5.2 billion by 2027, driven by the increasing demand for effective airflow management in industries such as manufacturing, automotive, and HVAC.

These fans operate on the principle of converting rotational kinetic energy into the flow energy of air, providing superior pressure capabilities compared to axial fans. Their ability to handle high volumes of air against significant resistance makes them invaluable in scenarios where air distribution and exhaust efficiency are critical. As industries strive for enhanced energy efficiency and operational performance, understanding the benefits of Centrifugal Air Fans becomes imperative for optimizing air management systems and ensuring compliance with environmental regulations.

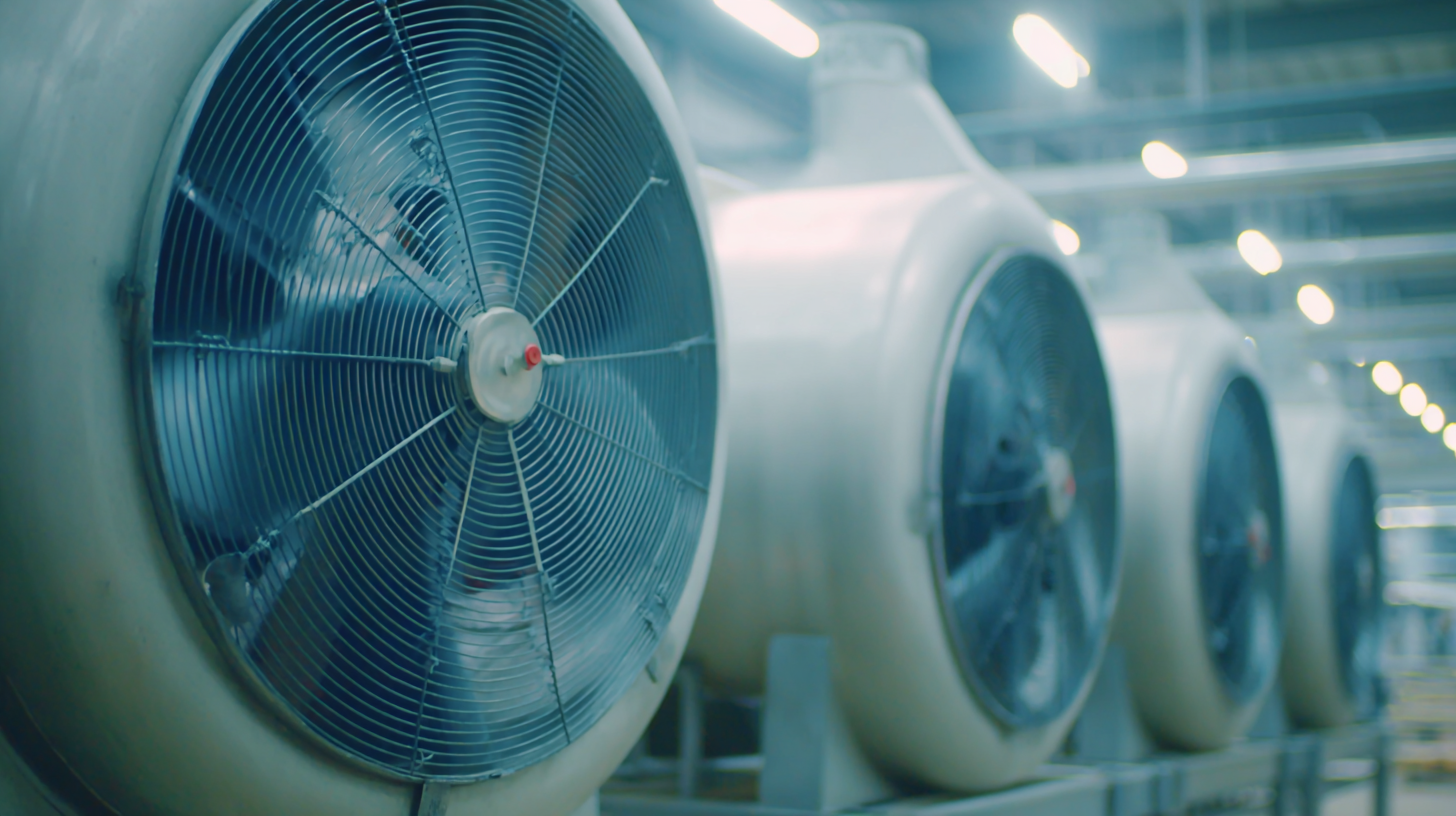

Centrifugal air fans play a critical role in various industrial applications, delivering numerous benefits that enhance operational efficiency. One of the key advantages is their ability to generate high airflow rates while maintaining a compact design. According to the Air Movement and Control Association (AMCA), centrifugal fans can provide up to 50% more airflow than comparable axial fans, making them ideal for spaces where air distribution is essential. This efficiency leads to improved ventilation and temperature control, which are crucial in environments such as manufacturing plants and processing facilities.

Another significant benefit of centrifugal air fans is their versatility. They are designed to handle a variety of air volumes and pressures, thus making them suitable for use in diverse applications including dust collection, fume extraction, and cooling systems. A recent report from MarketsandMarkets indicates that the global centrifugal fan market is expected to grow from $6.4 billion in 2021 to $8.1 billion by 2026, driven by increased demand across industries such as food processing and pharmaceuticals. This growth highlights the adaptability and reliability of centrifugal fans, solidifying their importance in maintaining safety and efficiency in industrial operations.

When evaluating the various types of fans used in industrial applications, centrifugal fans stand out for their efficiency and versatility. Unlike axial fans, which push air parallel to the rotor shaft, centrifugal fans generate airflow at a right angle to the intake. This design allows for higher pressure and is especially beneficial when working with systems that require extensive ductwork or in environments where dust and debris may be present.

**Tip:** Consider the complexity of your system’s layout; centrifugal fans are typically more suitable for longer duct runs due to their high static pressure capabilities.

When comparing centrifugal fans to other industrial fans, such as axial and mixed-flow fans, it is essential to assess the specific requirements of your application. Centrifugal fans provide superior airflow control and can handle varying load conditions more effectively. This adaptability makes them ideal for operations involving material handling, air processing, and ventilation systems.

**Tip:** Always factor in noise levels and energy efficiency when selecting a fan type, as centrifugal fans tend to operate quieter than axial fans while offering better energy savings over time.

Centrifugal air fans are integral to various industrial applications, notable for their efficiency and energy savings. According to a report by the U.S. Department of Energy, industrial fans and blowers account for approximately 15% of the total electricity consumption in manufacturing sectors. With advancements in technology, centrifugal fans have become more energy-efficient, often providing a reduction in energy usage by 20-50% compared to older models. This is primarily due to improved blade design and the integration of variable frequency drives, which enable fans to operate at optimal speeds depending on the demand.

Moreover, the implementation of centrifugal air fans can lead to substantial long-term operational savings. Research indicates that upgrading to energy-efficient centrifugal fans can reduce maintenance costs significantly, by as much as 30%, due to their reliable performance and longer lifespan. Additionally, the improved airflow and consistent pressure delivered by these fans enhance overall system efficiency, which can lead to increased productivity across various industrial processes. As industries continue to seek ways to cut costs and reduce their carbon footprint, the transition to centrifugal air fans presents a compelling case for both economic and environmental benefits.

This chart illustrates the benefits of centrifugal air fans in industrial applications, showcasing their efficiency, energy savings, cost savings, and noise levels. The data indicates that centrifugal fans can operate at an efficiency of around 85%, providing significant energy savings of 25% and potential cost savings up to $3000 annually, while maintaining a noise level of approximately 60 dB.

Centrifugal air fans play a vital role in various industrial applications, providing

efficient airflow management and temperature control. In the chemical processing industry, for example, these fans are

essential for ventilating hazardous fumes and ensuring workers' safety. According to a report by MarketsandMarkets,

the global centrifugal fan market is projected to grow from USD 2.5 billion in 2021 to USD 3.5 billion

by 2026, driven in part by the increasing demand for air handling solutions in chemical manufacturing.

In the HVAC sector, centrifugal fans are crucial for maintaining indoor air quality and energy efficiency. These fans are

commonly utilized in commercial buildings for heating, ventilation, and air conditioning systems. A study from the

American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) indicates that well-designed HVAC

systems with centrifugal fans can improve energy efficiency by up to 30%. This efficiency not only lowers

operational costs but also supports sustainability efforts in large-scale facilities.

Moreover, in the food processing industry, centrifugal fans are used to facilitate drying and cooling processes. A research

report by Allied Market Research states that the growing demand for processed food is anticipated to push the market for

air handling equipment, including centrifugal fans, reaching USD 14.6 billion by 2025. These fans ensure

that products are cooled efficiently, maintaining quality and extending shelf life, which is crucial for both manufacturers

and consumers alike.

To maximize the performance of centrifugal air fans in industrial applications, regular maintenance is crucial. A scheduled inspection can prevent potential issues that may arise from wear and tear. Start by cleaning the fan blades and housing to remove any dust, debris, or contaminants that could hinder airflow efficiency. Dirty components not only reduce performance but can also lead to overheating and increased energy consumption.

Additionally, pay attention to the lubrication of bearings and motor components. Proper lubrication ensures smooth operation and reduces friction, extending the life of the fan. Regularly checking and tightening all bolts and fasteners can also contribute to optimal performance, as loose connections may result in vibrations and operational inefficiencies. By implementing these maintenance tips, industrial operators can enhance the reliability and efficiency of centrifugal air fans, ultimately minimizing downtime and operational costs.