In recent years, the demand for energy-efficient air handling solutions has led to the increased adoption of Regenerative Air Blowers across various industries. These innovative devices are renowned for their ability to provide a consistent and robust airflow while minimizing energy consumption and operational costs. According to a report by the International Energy Agency, improved air handling systems can achieve energy savings of up to 30%, making the implementation of technologies like the Regenerative Air Blower not only an economically sound decision but also an environmentally responsible one.

Dr. Emily Carter, an industry expert in pneumatic systems, states, "The advancements in Regenerative Air Blower technology represent a significant opportunity for industries to enhance their air handling efficiency while reducing their carbon footprints." This statement underscores the trend of integrating sustainable practices within manufacturing and processing sectors. The architecture of Regenerative Air Blowers, which utilizes multiple stages of air compression, results in lower noise levels and higher operational reliability, further solidifying their role as a frontrunner in the realm of efficient air handling solutions.

As companies strive to meet stricter environmental regulations and operational efficiency goals, the Regenerative Air Blower stands out as a pivotal component in achieving these objectives. The focus on adopting such advanced technologies is not merely a trend; it reflects a broader commitment to sustainability and cost-effective performance in industrial air management systems.

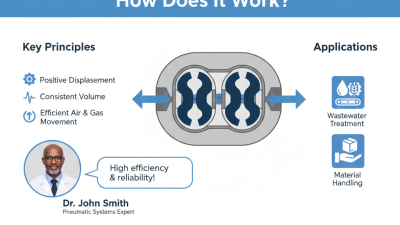

Regenerative air blowers are a type of centrifugal blower that utilize a unique operating principle to move air efficiently. They consist of multiple stages, each designed to increase the pressure of the air by harnessing the energy created during the impeller's rotation. This mechanism allows for the transfer of kinetic energy to the air, resulting in a continuous flow with minimal energy loss. The design typically features a compact structure that enhances durability and reduces the need for maintenance.

In terms of functionality, regenerative air blowers are characterized by their ability to provide high volumes of air at relatively low noise levels. They operate by drawing air into the inlet, accelerating it through a series of impellers, and then discharging it at a higher pressure. This makes them ideal for various applications, including wastewater treatment, pneumatic conveying, and cooling processes. The efficiency of these blowers not only contributes to lower operational costs but also supports sustainability efforts by minimizing energy consumption during air handling processes.

Regenerative air blowers have gained recognition in various industries for their ability to enhance air handling efficiency. One of the key advantages of these blowers is their energy efficiency. According to a report by the U.S. Department of Energy, regenerative blowers can save up to 30% more energy compared to traditional air moving solutions. This efficiency is crucial for companies striving to reduce operational costs while minimizing their environmental footprint. The blowers utilize a unique design that allows them to recirculate air, thereby requiring less energy to maintain desired pressure levels.

Another significant benefit of regenerative air blowers lies in their low maintenance requirements. A study from the Institute of Clean Air Companies highlights that these devices have fewer moving parts than conventional blowers, leading to reduced wear and tear over time. Consequently, users can expect longer service intervals and lower maintenance costs. Furthermore, the quiet operation of regenerative blowers makes them suitable for installations in noise-sensitive environments. As industries increasingly prioritize sustainable practices, the advantages of regenerative air blowers position them as a preferable choice for effective air handling solutions.

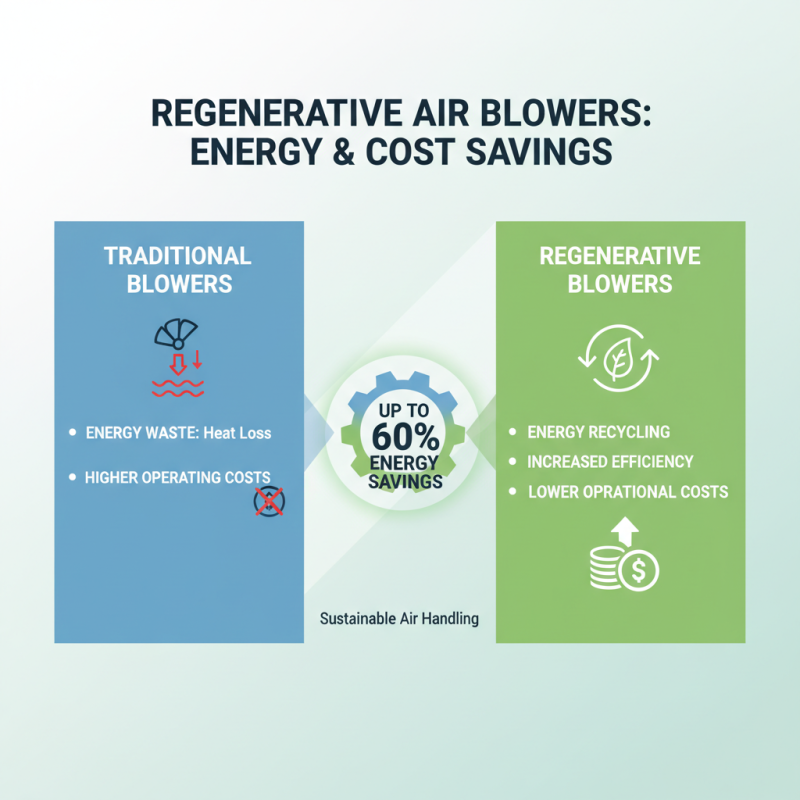

Regenerative air blowers are becoming increasingly popular in various industries due to their impressive energy efficiency and cost-saving capabilities. Unlike traditional blowers that waste a significant portion of energy through heat loss, regenerative air blowers operate on a unique principle that captures and recycles energy. This process not only minimizes energy consumption but also ensures that air handling systems operate at optimal efficiency, leading to lower operational costs over time.

The direct correlation between energy efficiency and cost savings cannot be overstated. By employing regenerative air blowers, businesses can significantly reduce their electricity bills, translating to substantial annual savings. Additionally, the reduced energy requirement lessens the carbon footprint of industrial operations, making these blowers an environmentally friendly choice. Furthermore, their durability and minimal maintenance needs contribute to further cost reductions by decreasing the frequency and costs of repairs or replacements. Ultimately, investing in regenerative air blowers not only promotes economic advantages but also aligns with sustainability goals in today's eco-conscious market.

Regenerative air blowers have found diverse applications across various industries due to their efficiency and effectiveness in air handling. In the manufacturing sector, these blowers are commonly used for pneumatic conveying processes. They facilitate the movement of materials through pipes, ensuring consistent flow and reducing downtime. Their ability to generate high airflow at low power consumption makes them an ideal choice for operations such as ash handling, where they help maintain optimal efficiency.

In the food and beverage industry, regenerative air blowers play a crucial role in maintaining hygiene and process efficiency. They are utilized in packaging lines to remove dust and debris from products, ensuring that items are clean and ready for shipment. Additionally, these blowers can assist in cooling processes during production, helping to maintain product quality. Their quiet operation further enhances the workplace environment, making them suitable for environments where noise levels must be minimized.

Another significant application of regenerative air blowers is in the wastewater treatment sector. They are essential in aeration processes, supporting the biological treatment of wastewater by providing much-needed oxygen to microorganisms. This contributes to improved treatment efficiency and reduced energy costs, showcasing the blowers' contribution to sustainable practices. The versatility and reliability of regenerative air blowers across these diverse applications highlight their importance in modern industrial operations.

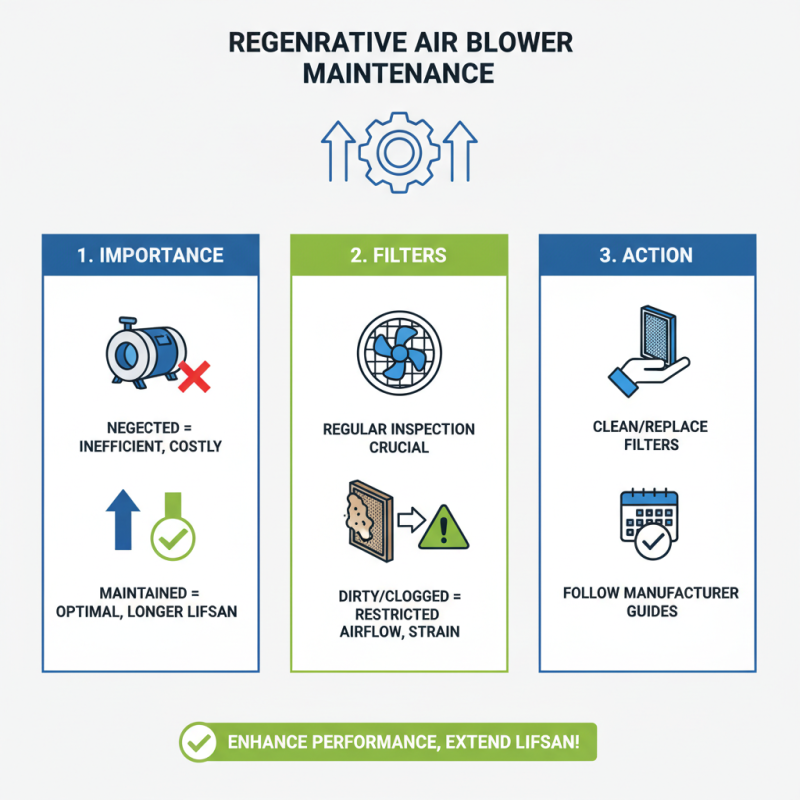

Maintenance is crucial for ensuring the optimal performance of regenerative air blowers, as neglecting it can lead to decreased efficiency and increased operational costs. Regular inspection of the blower’s filters is essential; dirty or clogged filters can restrict airflow and place unnecessary strain on the system. Cleaning or replacing filters according to the manufacturer’s recommendations not only enhances performance but also extends the lifespan of the blower.

Another important aspect of maintenance involves checking the mechanical components, such as bearings and seals. Over time, wear and tear can cause these parts to degrade, leading to increased noise levels and potential system failures. Implementing a routine lubrication schedule and monitoring for any unusual sounds can help identify issues early. Additionally, ensuring that the blower is operating within specified parameters—such as pressure and temperature—can prevent damage and maintain efficiency during operation. Prioritizing these maintenance tasks will ultimately result in a more reliable and effective air handling solution.