In today's competitive business environment, efficiency is crucial. Companies need reliable equipment to optimize operations. One such equipment is the Regenerative Blower, a powerful tool that offers significant advantages. It’s designed to provide high air volume with low energy consumption.

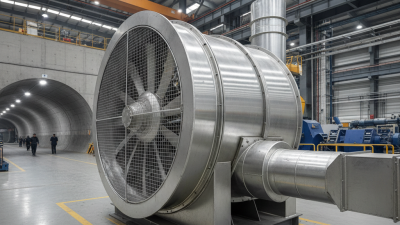

Regenerative Blowers are versatile. They can be used for applications like wastewater treatment, material handling, and drying processes. Their compact design and quiet operation make them ideal for various industries. However, not every business may realize their full potential. Some might overlook maintenance, leading to suboptimal performance.

Understanding the benefits of a Regenerative Blower can lead to better decisions. Increased productivity and reduced costs are essential for growth. As businesses face challenges, investing in efficient technology is necessary. Failing to adopt such tools could mean falling behind competitors. The Regenerative Blower stands out as a solution worth considering.

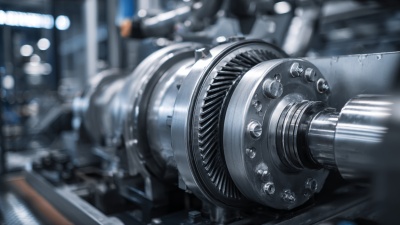

Regenerative blowers offer several advantages for industrial applications. These blowers are efficient in moving air and gases, making them essential in various settings. The efficiency rate can reach 70-90%, significantly reducing energy costs. Many industries opt for regenerative blowers for tasks like aeration and material handling due to their reliability and low maintenance needs.

One major benefit is their compact design. They take up less space than traditional options, crucial for facilities with limited layout. The quiet operation is another advantage; they operate at lower decibel levels, allowing for a safer work environment. Reports indicate that employee productivity increases in quieter settings, emphasizing this point.

Tip: Regular maintenance, even if minimal, is essential. Simple checks can prevent costly breakdowns. Keep an eye out for unusual noises or vibrations. These could indicate issues needing immediate attention.

Incorporating regenerative blowers may require upfront investments. However, the long-term savings can be significant. Yet, businesses must assess their specific needs before making the switch. Not every application will benefit equally. Evaluating efficiency and potential return on investment is critical. This reflection can guide better decision-making for your needs.

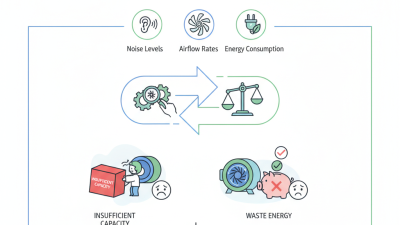

The regenerative blower is a game changer for businesses seeking energy efficiency. According to recent industry reports, these blowers can reduce energy consumption by as much as 30%. This efficiency directly translates to significant cost savings. For example, in a manufacturing setting, switching to a regenerative blower can cut electricity bills substantially.

While many companies notice immediate savings, some may overlook long-term benefits. The lifespan of regenerative blowers is typically longer than traditional options. This longevity further minimizes maintenance costs. In fact, data suggests that effective selection can lead to maintenance frequency reductions by 50%.

Yet, not every business may achieve optimal results. Proper installation is crucial for maximizing efficiency. Improper setup can negate gains and lead to wasted energy. This is an essential aspect to monitor. Continuous analysis and adjustment ensure that businesses reap the full financial rewards.

Regenerative blowers are gaining traction in various industries due to their reduced maintenance needs. These blowers operate on a simple principle, drawing in air and compressing it without many moving parts. This design leads to fewer mechanical failures and less downtime.

According to a recent industry report, regenerative blowers can experience maintenance intervals that are 50% longer than traditional models. This means businesses can save substantially on service costs. Regular inspections are still necessary, but the overall frequency is much lower. Many operators enjoy a significant reduction in labor hours needed for maintenance.

Moreover, with fewer components prone to wear and tear, businesses can rely on these blowers for a more extended period. The expected lifespan can exceed 10 years with proper care. However, some users report challenges with initial setup and fine-tuning. These issues can lead to frustration, highlighting the importance of proper installation and operator training. Still, the long-term benefits outweigh these initial hurdles.

Regenerative blowers offer remarkable versatility across various industries. They can be used in applications such as wastewater treatment, packaging, and material handling. These blowers provide consistent airflow and pressure, making them ideal for tasks that require reliable performance. In wastewater treatment, they aid in aeration processes, ensuring that facilities operate efficiently.

Another area where regenerative blowers excel is in food packaging. Their ability to create a vacuum or positive pressure helps maintain freshness and extend shelf life. This application shows how they contribute to reducing waste. However, businesses must select the right blower model for specific needs, which can be challenging.

In the realm of materials handling, regenerative blowers effectively transport lightweight materials. They move items like plastic pellets or powders through pipelines. This process can enhance productivity but may require regular maintenance to ensure optimal performance. The balancing act of efficiency and upkeep can lead to areas of improvement for many operations.

Regenerative blowers are gaining popularity in various industries for their efficient performance. One of the standout advantages is improved airflow control. These blowers allow precise adjustments to airflow, catering to different operational needs. This flexibility ensures that businesses can optimize their processes, whether in packaging, pneumatic conveying, or wastewater treatment.

Noise reduction is another compelling benefit. Traditional blowers often produce excessive sound, causing disruptions in the work environment. In contrast, regenerative blowers operate more quietly, creating a more pleasant atmosphere. This feature is crucial for industries where concentration is vital. Workers can communicate effectively without shouting over loud machinery.

However, it’s important to acknowledge potential limitations. Some may find initial costs higher compared to other blower types. In certain setups, the lower air pressure could be a factor. Regular maintenance is necessary to sustain performance. Evaluating these aspects can help businesses make informed decisions on their airflow needs.

| Benefit | Description | Impact on Business |

|---|---|---|

| Improved Airflow Control | Enhanced precision in airflow management for various industrial applications. | Increases efficiency, contributing to higher productivity levels. |

| Noise Reduction | Lower operational noise levels compared to traditional blowers. | Creates a better working environment, improving employee satisfaction. |

| Energy Efficiency | Utilizes less energy while providing the same or higher performance output. | Reduces operational costs, leading to savings over time. |

| Compact Design | Space-saving configurations suitable for various installations. | Optimizes workspace, allowing for better layout and equipment arrangement. |

| Versatile Applications | Applicable in various sectors such as food processing, packaging, and wastewater treatment. | Expands operational capabilities and market opportunities. |