In the world of industrial applications, choosing the right equipment is crucial. A Regenerative Blower stands out for its efficiency and versatility. These blowers are designed to provide consistent airflow, making them ideal for various settings. Their ability to generate air pressure without worrying about heavy maintenance makes them a popular choice.

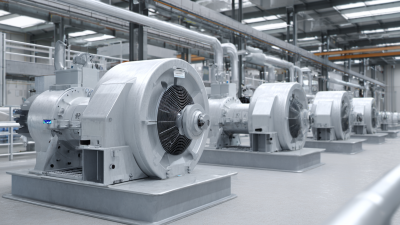

Many businesses rely on Regenerative Blowers for essential processes. They are commonly used in wastewater treatment, pneumatic conveying, and material handling. The design of these blowers allows for quiet operation and energy efficiency. However, not all blowers are created equal, and selecting the best one requires thoughtful consideration.

Understanding the specific industrial needs is vital. Factors such as airflow requirements, energy consumption, and space constraints need attention. While some brands dominate the market, others may offer unique features worth exploring. With plenty of options available, doing thorough research can lead to the ideal choice. Each Regenerative Blower level has its strengths and weaknesses, making an informed decision necessary.

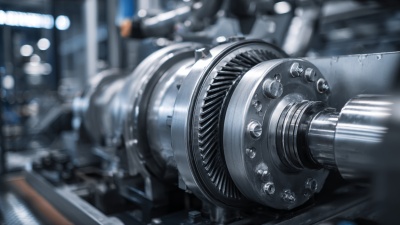

Regenerative blowers are essential for various industrial applications. They function by drawing in air and expelling it at a higher pressure. This process creates a continuous flow of air, making them suitable for tasks like material handling, drying, and vacuum applications. The unique design contributes to high efficiency and low noise levels, attracting many industries.

These blowers utilize centrifugal forces and a series of impellers to move air. The air is compressed in chambers, creating pressure before being released. This principle promotes energy savings, but sometimes the units can be overlooked in maintenance. Users may experience reduced performance if they neglect regular checks. Frequent wear and tear can also lead to unexpected downtime in production.

Moreover, selecting the right specifications for specific needs can be challenging. Some may struggle with airflow requirements versus energy consumption. Ensuring the blower fits the application's demands may require trial and adjustment. In a real-world setting, efficiency can be dynamic, and assumptions about capability may fall short.

This chart represents various applications and flow rates of regenerative blowers ideal for industrial usage. The data illustrates how different models cater to specific operational needs.

When selecting a regenerative blower for industrial needs, there are key features to consider. Look for the blower's efficiency rating. High efficiency can save energy costs. Noise levels also matter, especially in a work environment. A quieter unit is often preferable.

Tip: Compare decibel levels before making a decision. You don’t want a loud blower disrupting your operations. Check the maximum flow rate as well. It should meet your specific requirements without overloading.

Another important factor is build quality. Durable materials ensure longevity. Some blowers may be prone to wear. This can lead to more frequent repairs. Look for models with a solid warranty. It reflects the manufacturer's confidence in their product.

Tip: Request user reviews to gauge reliability and performance. Take note of any common complaints. An informed choice can prevent issues down the road. Always consider your specific application needs too. Each industry has unique demands.

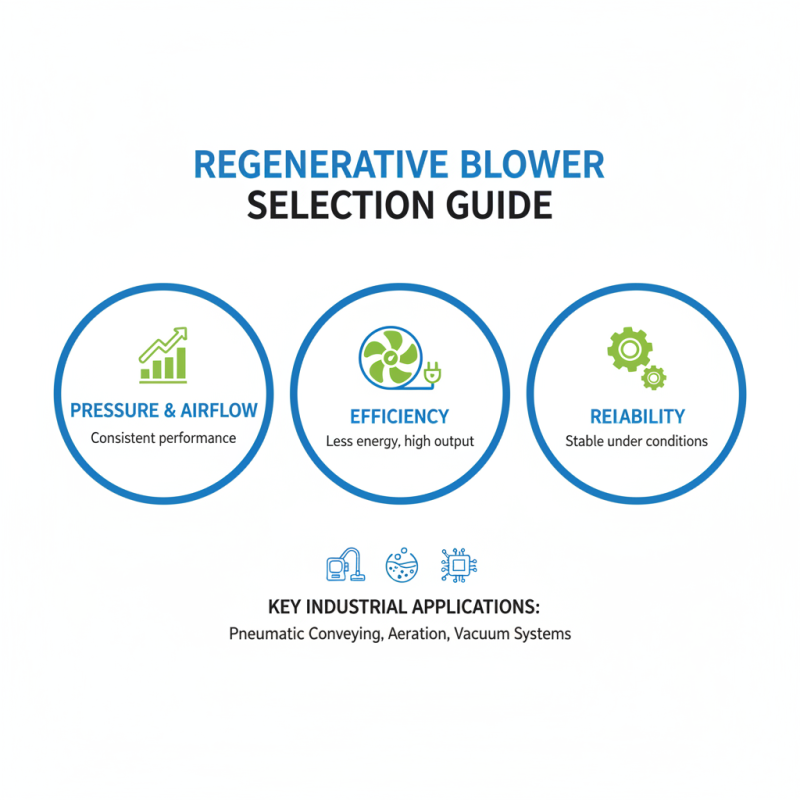

When selecting regenerative blowers, several performance specifications are essential. These devices are crucial in various industrial applications. Consider the pressure and airflow ratings. Look for models that provide consistent performance under varying conditions. Efficiency matters, too. A blower that consumes less energy while delivering high output is more desirable.

Another key aspect is noise level. Some blowers operate quietly, making them suitable for noise-sensitive environments. Pay attention to the dimensions and weight. Compact designs can save space but might sacrifice power. Watch for maintenance requirements. Frequent upkeep can increase operational costs over time. Reflect on the parts’ durability, as this impacts long-term viability.

Finally, consider the installation process. Some models are complex and may require professional assistance. Ease of installation can affect overall costs. Each characteristic matters. A balance between specifications and practical needs is often not straightforward. Make informed choices by considering real-world applications and user experiences.

When evaluating regenerative blowers for industrial applications, it's essential to compare various brands and models. Look for specifications like airflow capacity and pressure ratings. Consider how these factors affect efficiency in your operations. Some blowers are quieter, which can be important in noise-sensitive environments. Others may offer different energy consumption profiles that could impact your operational costs.

The design of the blower also matters. Some models feature advanced impeller designs that improve performance. A few models struggle with heat dissipation. This can lead to reduced reliability over time. Look for models with robust construction to ensure longevity. Users often report that ease of maintenance varies widely. Routine servicing can become tedious if the blower is not designed for straightforward access.

Not all regenerative blowers are created equal. Some brands excel in high-pressure environments, while others perform better in low-flow applications. It’s key to identify your specific needs before making a selection. Feedback from industry peers can highlight useful insights. It's important to weigh both expert reviews and user experiences during your decision-making process.

| Model | Air Flow (Cubic Feet per Minute) | Max Pressure (psi) | Noise Level (dB) | Weight (lbs) | Warranty (Years) |

|---|---|---|---|---|---|

| Model 1 | 150 | 10 | 75 | 50 | 2 |

| Model 2 | 200 | 12 | 70 | 55 | 3 |

| Model 3 | 180 | 11 | 72 | 52 | 2 |

| Model 4 | 220 | 13 | 68 | 60 | 3 |

| Model 5 | 170 | 9 | 74 | 53 | 2 |

| Model 6 | 160 | 8 | 76 | 58 | 1 |

| Model 7 | 190 | 10 | 73 | 57 | 2 |

| Model 8 | 210 | 11 | 69 | 62 | 3 |

| Model 9 | 130 | 7 | 78 | 48 | 1 |

| Model 10 | 175 | 9 | 72 | 54 | 2 |

Regular maintenance is crucial for the optimal performance of regenerative blowers. Start by checking the air filters. Clogged filters can lead to decreased efficiency and increased energy consumption. Cleaning or replacing them can significantly improve airflow. Additionally, ensure that all connections are secure. Loose fittings may cause air leaks, resulting in reduced pressure and potential damage.

Another important aspect is monitoring the oil levels in the lubrication system. Insufficient lubrication can lead to overheating and wear. Follow the manufacturer's guidelines on oil changes and levels. Pay attention to unusual noises during operation; these can signal underlying issues. Early detection is key to preventing costly repairs.

Don’t overlook the need for regular inspections. Check for vibrations and abnormal wear on the impeller. Proper alignment and balance are vital to avoid excess strain on the motor. Keeping a detailed log of maintenance activities can help spot patterns and predict issues. Reflection on past problems can lead to better practices in the future. Remember, even small details matter in maintaining efficiency.