Centrifugal Air Fans play a crucial role in various industrial applications, optimizing air flow and enhancing operational efficiency. As detailed in the "Fan Efficiency Report 2022" by the International Energy Agency, centrifugal fans account for approximately 25% of the total energy consumption in ventilation systems across manufacturing and HVAC sectors. This significant percentage underscores the necessity for understanding not just their functionality but also the science behind their design and performance.

Centrifugal Air Fans play a crucial role in various industrial applications, optimizing air flow and enhancing operational efficiency. As detailed in the "Fan Efficiency Report 2022" by the International Energy Agency, centrifugal fans account for approximately 25% of the total energy consumption in ventilation systems across manufacturing and HVAC sectors. This significant percentage underscores the necessity for understanding not just their functionality but also the science behind their design and performance.

In an era focused on energy conservation and sustainability, advancements in centrifugal air fan technology are pivotal. Reports indicate that modern centrifugal fans can achieve efficiency levels as high as 85%, suggesting that selecting the appropriate model can substantially reduce energy costs while maintaining system reliability. This article delves into the underlying science of centrifugal air fans, examining their efficiency metrics and diverse applications to provide valuable insights for industry professionals.

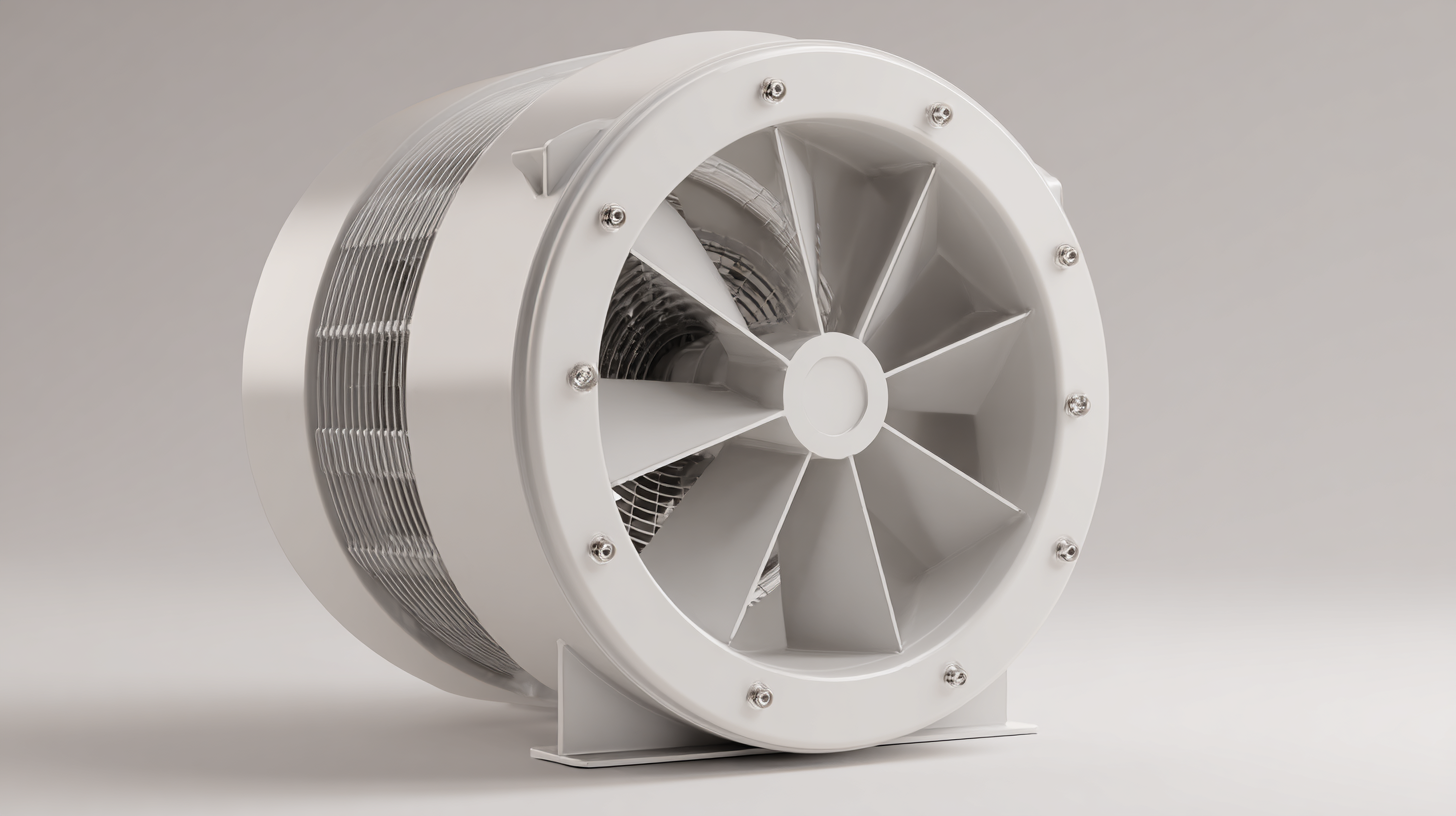

Centrifugal air fans are pivotal in various industrial applications, providing efficient air movement through their unique design principles. Unlike axial fans, centrifugal fans generate a large volume of airflow at increased pressure, resulting from the kinetic energy imparted by the rotating impeller. This design, which typically involves a scroll housing, allows for a more compact and robust configuration, making them ideal for locations where space is limited. According to the American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE), centrifugal fans can achieve total efficiencies exceeding 80%, particularly in high-pressure applications.

The performance of centrifugal air fans is influenced significantly by their blade design, speed, and size. Data from the Industrial Energy Technology Conference suggests that fans utilizing backward-curved blades provide optimal air performance and energy efficiency, reducing operational costs by up to 20% in some cases. Moreover, advancements in materials and manufacturing processes have led to lighter, more durable fan constructions, further enhancing performance. With their reliability and efficiency, centrifugal fans are extensively used in HVAC systems, material handling, and wastewater treatment processes, underscoring their versatility in meeting modern industrial demands.

The efficiency of centrifugal air fans is significantly influenced by several key factors, which play a crucial role in their performance and applications across various industries. One of the primary determinants is the fan design itself, including blade shape, angle, and material. Aerodynamically optimized blades reduce turbulence and enhance airflow, ultimately leading to better energy efficiency.

Moreover, the impeller diameter and rotation speed also contribute to the fan’s performance, where larger diameter fans generally deliver higher volumes of air at lower speeds, minimizing energy consumption.

Moreover, the impeller diameter and rotation speed also contribute to the fan’s performance, where larger diameter fans generally deliver higher volumes of air at lower speeds, minimizing energy consumption.

Another essential factor is the operating environment and system layout. The placement of the fan in relation to ductwork and other components can affect resistance and flow dynamics. Ensuring that the fan operates within its optimal range and is correctly matched to the system’s pressure requirements is critical for maximizing efficiency. Additionally, regular maintenance and adjustments to accommodate changes in operating conditions, such as temperature and pressure, are vital for sustaining performance. By understanding these factors, industries can leverage centrifugal air fans effectively, enhancing their operational efficiency and energy savings.

Centrifugal air fans are widely utilized across various industries, thanks to their ability to move air efficiently and handle high resistance installations. The HVAC sector is perhaps one of the most prominent users; these fans play a crucial role in maintaining indoor air quality and thermal comfort. According to a report by the Global Ventilation Fan Market, the demand for centrifugal fans in HVAC applications is projected to grow significantly, driven by increasing construction activities and an urgent need for energy-efficient systems.

In addition to HVAC, centrifugal air fans are integral to the manufacturing and process industries. They are frequently employed in dust collection systems, ensuring clean, breathable air in facilities such as cement plants and metalworking shops. Data from a recent industry analysis shows that the use of centrifugal fans in dust control applications is expected to increase by 5% annually, reflecting a growing awareness of workplace safety and regulatory compliance. Furthermore, these fans are essential in cooling systems for power generation, where they help maintain optimal operational temperatures, thereby boosting efficiency and prolonging equipment lifespan in high-demand environments.

Centrifugal fans are a popular choice in various industrial applications due to their efficient design and ability to handle large volumes of air against substantial resistance. When comparing centrifugal fans with axial fans, the differences become clear: centrifugal fans operate by converting rotational energy into airflow, allowing for increased pressure capacity. This makes them ideal for high-static pressure applications such as HVAC systems, dust collection, and material handling, where effective air movement is crucial.

On the other hand, axial fans, which generate airflow parallel to their axis, excel in low-pressure applications. They are lighter and often more energy-efficient for scenarios requiring large air volume movement without significant resistance. Moreover, the simplicity of their design contributes to their lower initial costs and maintenance.

In contrast, centrifugal fans, while more complex and potentially more costly, provide superior performance in environments where air needs to be forced through filters or ducts. Each fan type has its unique advantages, making the choice largely dependent on the specific application requirements and desired efficiency levels.

Recent innovations in centrifugal air fan technology have significantly enhanced their efficiency and performance across various applications. One of the key advancements is the integration of advanced materials and design techniques that reduce weight and enhance durability. For instance, the use of composite materials allows fans to operate at higher speeds with reduced energy consumption, translating to lower operational costs. Additionally, new aerodynamic blade designs have been developed to optimize airflow patterns, resulting in improved pressure generation while minimizing noise levels.

Another important area of progress is the implementation of smart technologies in centrifugal fans. Modern fans are increasingly equipped with IoT capabilities and variable frequency drives (VFDs), allowing for real-time monitoring and precise control of airflow based on real-time environmental conditions. This adaptability not only boosts energy efficiency but also enables fans to respond dynamically to changing demands, making them well-suited for critical applications such as HVAC systems, industrial processes, and even renewable energy sectors. These innovations point towards a future where centrifugal air fans are more efficient, versatile, and integral to energy-saving strategies in various industries.