Centrifugal fans play a crucial role in many industries, providing efficient air movement solutions. Dr. Emily Carter, an expert in airflow systems, states, "Understanding centrifugal fans is essential for optimizing air handling." This highlights their importance in design and engineering.

A centrifugal fan operates on a straightforward principle. It draws air in through the center and expels it at high speed out of the side. This movement creates a strong airflow, perfect for ventilation and cooling. However, achieving the right balance in design can be challenging.

Consider the intricacies of fan design. Issues like noise, efficiency, and maintenance often arise. Engineers must continuously adapt to evolving technologies. Real-world applications reveal that even minor design flaws can lead to significant performance drops. Thus, understanding centrifugal fans is not just academic; it involves practical implications that demand attention.

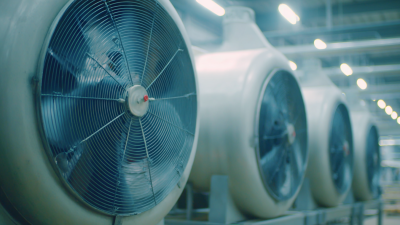

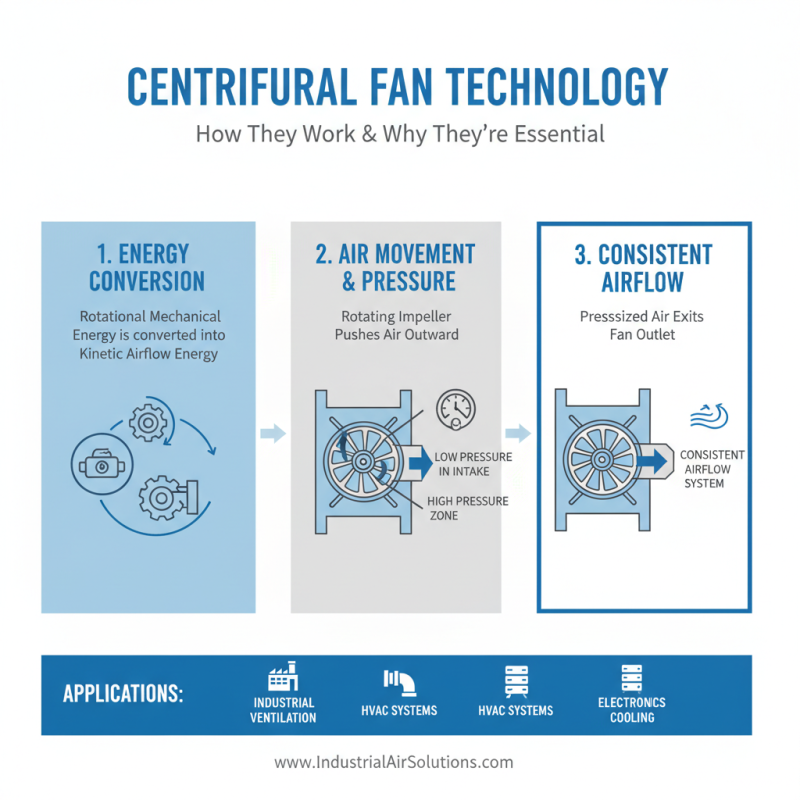

Centrifugal fans are vital in various industrial and commercial applications. These fans generate airflow by converting rotational energy into kinetic energy. A rotating impeller pushes air outward, creating a high-pressure area. The air then exits through the fan outlet, resulting in a consistent airflow.

According to a report by Technavio, the global centrifugal fan market is projected to grow by over 5% annually. This growth highlights the increasing demand for ventilation systems in manufacturing and HVAC. Centrifugal fans efficiently move air, which is essential in dust control, fume extraction, and general ventilation.

Despite their benefits, centrifugal fans have challenges. Noise can be an issue, particularly in residential applications. Improper sizing may lead to energy inefficiencies. Selecting the right fan type and configuration is crucial for effectiveness. Many systems fail to address these factors, resulting in subpar performance. Understanding the dynamics of centrifugal fans aids in optimizing their usage across various industries.

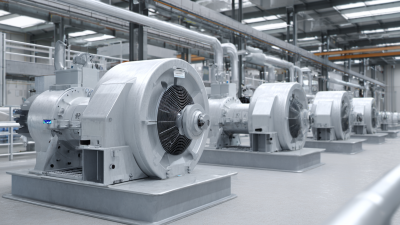

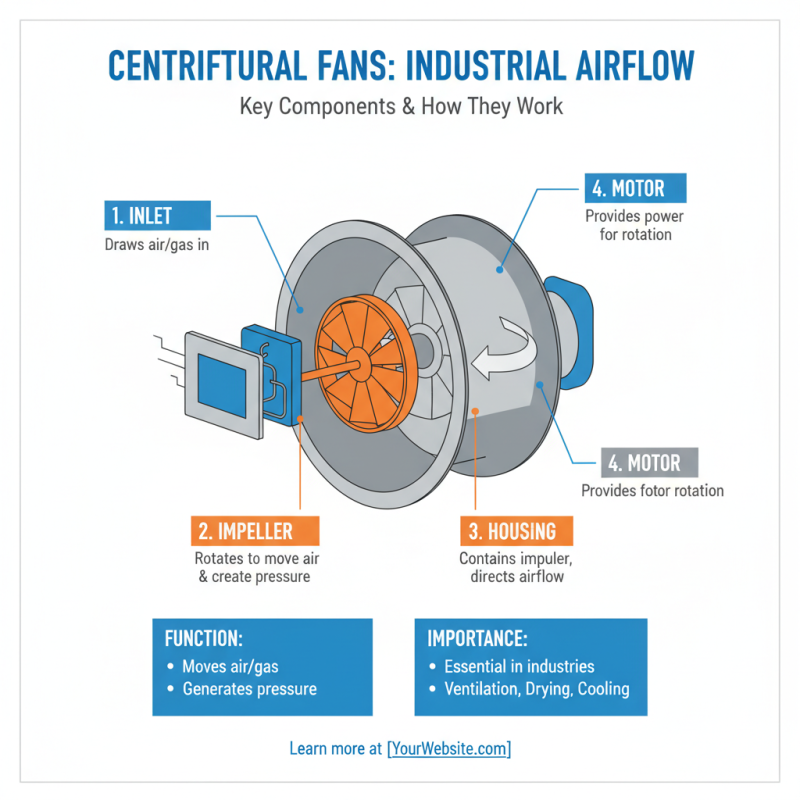

Centrifugal fans are essential in various industries. They move air or gas through a system using rotating blades. Understanding their basic components is crucial for effective use. Key parts include the impeller, housing, motor, and inlet. The impeller drives airflow, creating pressure. Housing contains the impeller and directs air. Motors provide the necessary power.

The efficiency of these fans can significantly impact energy consumption. A report from the U.S. Department of Energy estimates that proper fan selection and maintenance can save up to 30% in energy costs. However, many facilities overlook this. Regular maintenance is often neglected. Dust buildup can reduce efficiency, causing overheating. A clean impeller can improve performance.

Another critical component is the inlet, which affects airflow. Properly designed inlets minimize turbulence. This enhances performance and reduces noise levels. Unfortunately, misalignment is common. It can create vibration issues over time. Such problems diminish the fan's lifespan and increase repair costs. Being aware of these components helps in making informed decisions.

Centrifugal fans play a vital role in various industries by creating airflow through a unique mechanism. These fans utilize a rotating impeller to draw air in and then accelerate it towards the outlet. According to the American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE), centrifugal fans are responsible for a significant portion of the air movement in commercial HVAC systems. This makes understanding their functionality crucial for effective system design.

The process starts when air enters the fan through the inlet. As the impeller spins, it forces the air outward, increasing its velocity. The shape of the fan blades contributes to this process, allowing for efficient airflow. Research indicates that nearly 80% of airflow efficiency can be achieved with optimized blade design. However, manufacturers often overlook the implications of improper sizing or installation, which can lead to performance losses.

Moreover, centrifugal fans can operate at various speeds, allowing them to adapt to different airflow requirements. This flexibility is vital in applications like dust collection or chemical processes. Data suggests that approximately 20% of industrial energy consumption is linked to ventilation, highlighting the need for precise airflow generation. Despite this, many installations fail to consider maintenance, leading to reduced efficiency and increased operational costs.

| Fan Type | Application | Airflow Capacity (CFM) | Efficiency (%) | Noise Level (dBA) |

|---|---|---|---|---|

| Forward Curved | HVAC Systems | 300 - 2000 | 50 - 60 | 40 - 60 |

| Radial | Industrial Exhaust | 1000 - 6000 | 70 - 85 | 60 - 80 |

| Backward Curved | Material Handling | 500 - 5000 | 80 - 90 | 50 - 70 |

| Mixed Flow | Cooling Towers | 800 - 4000 | 60 - 75 | 45 - 65 |

Centrifugal fans are critical in many industries. They move air or gas efficiently and are widely used in HVAC systems. Factories rely on these fans to ventilate spaces and remove harmful fumes. In woodworking, dust collection systems use centrifugal fans to maintain a cleaner environment. This promotes safety and helps the workers breathe easier.

In the food processing industry, these fans help maintain air quality. They circulate air to keep products fresh. During drying processes, they play a key role by ensuring even airflow. However, not every application sees optimal performance. Sometimes, fans may create excessive noise or require more energy than expected. It's important to evaluate their efficiency regularly.

In wastewater treatment, centrifugal fans help aerate tanks. They promote the growth of bacteria that break down waste. Yet, they can also face maintenance challenges. Blockages can reduce airflow, causing inefficiencies. Regular inspections are needed to ensure they function properly. Understanding these aspects can improve overall processes.

Centrifugal fans are critical in various industries. They require regular maintenance to function efficiently. Neglecting this can lead to breakdowns or reduced performance, causing costly downtime.

One key maintenance tip is to inspect fan blades regularly. Dust and debris can accumulate over time. A buildup affects airflow and increases energy consumption by up to 10%. Regularly cleaning the blades helps maintain optimal performance. Another essential step is checking for vibrations. Excessive vibrations can indicate imbalanced blades or worn bearings. According to recent industry studies, vibration issues can decrease a fan’s lifespan by about 50%.

Lubrication is another vital aspect of maintenance. Bearings need proper lubrication to reduce friction. Insufficient lubrication can lead to overheating and damage. It’s advisable to check lubricant levels every month. A lack of regular maintenance can lead to unexpected failures. Operating under such conditions can not only harm the equipment but also compromise worker safety. Developing a routine maintenance schedule is beneficial for both performance and safety.

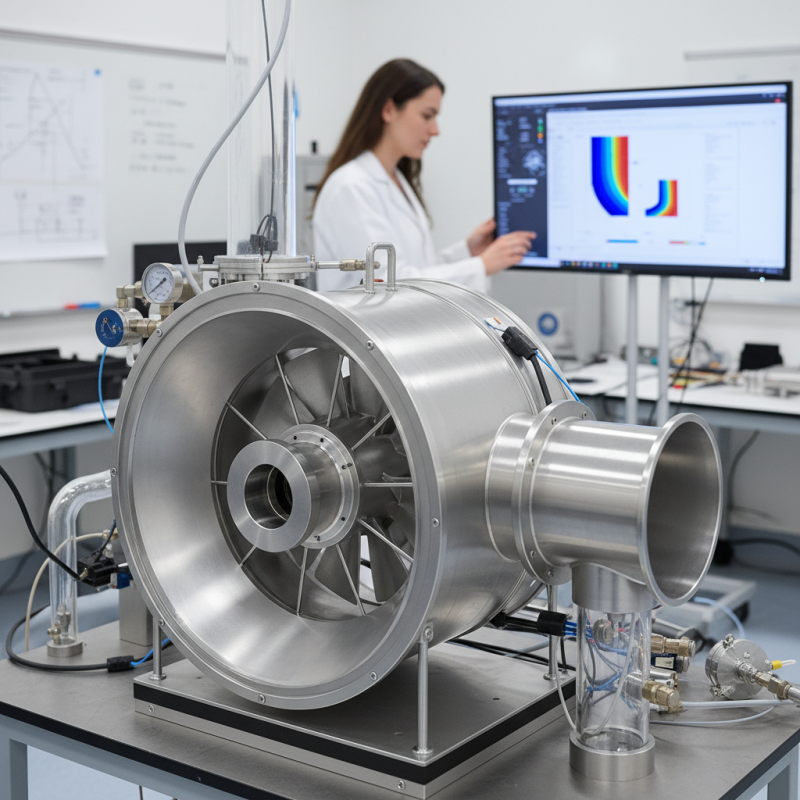

This chart represents the performance of centrifugal fans at different speeds (RPM) in terms of airflow (CFM) and static pressure (inches of water). The data illustrates how fan efficiency changes with varying speeds.