Centrifugal Ventilation Fans are essential in various industries. Their role in air movement cannot be overstated. According to Dr. Emily Carter, an expert in ventilation technology, "Centrifugal Ventilation Fans optimize airflow in complex environments." This statement highlights their significance in ensuring proper ventilation.

These fans utilize a unique design to enhance air pressure and flow. They are favored in settings where efficient air distribution is crucial, such as factories and tunnels. The fan blades are positioned to draw air in and expel it at high velocity. This process is vital for maintaining air quality and controlling temperature.

However, it's important to note that not all ventilation systems are effective. A poorly designed Centrifugal Ventilation Fan may cause airflow issues. Businesses must assess their needs carefully. They should explore potential inefficiencies and balance fan capabilities with space requirements. Choices in fan size and speed can impact their effectiveness and energy consumption. Understanding these elements is key to optimizing air movement in any setting.

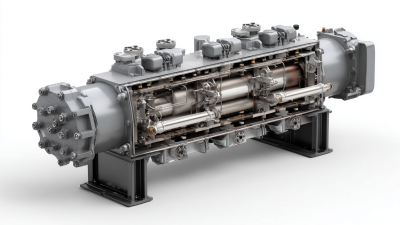

Centrifugal ventilation fans are essential in various industrial applications. They excel in moving large volumes of air with high efficiency. These fans utilize a rotating impeller to increase air pressure and direct airflow. The unique design allows them to handle the resistance of ducting and filters, making them suitable for demanding environments.

Industry reports indicate that centrifugal fans can achieve efficiency ratings ranging from 60% to 85%. This efficiency is crucial for reducing energy consumption in large systems. In data centers, for instance, effective ventilation is necessary to maintain optimal temperatures, as high temperatures can reduce equipment lifespan significantly. The energy costs associated with poor ventilation can exceed thousands of dollars annually.

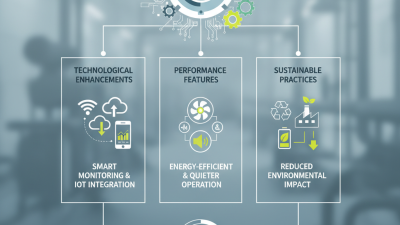

Despite their advantages, centrifugal fans are not without limitations. Noise levels can be an issue, especially in residential settings. The operating sound might be bothersome if not properly managed. Additionally, improper installation can lead to decreased performance. Regular maintenance is crucial to ensure they operate at peak efficiency. Reflecting on these factors is vital for choosing the right system.

Centrifugal ventilation fans play a vital role in various environments. They move air efficiently, creating airflow where it's needed. The principle behind their operation is fascinating. These fans utilize centrifugal force to propel air outwards, a process that begins when the blades rotate.

As the fan blades spin, they draw in air from the center. This air passes over the rotating blades, gaining momentum. Once the air reaches the outer edge of the fan, it exits at a high speed. This motion generates a consistent airflow. The design of these fans allows for handling larger volumes of air compared to others.

However, not all designs are perfect. Some centrifugal fans can be noisy. This noise may be uncomfortable in quieter environments. Additionally, if not maintained properly, they can accumulate dust and dirt, reducing efficiency over time. Regular checks can help mitigate these issues. Understanding these nuances is crucial for anyone considering their implementation.

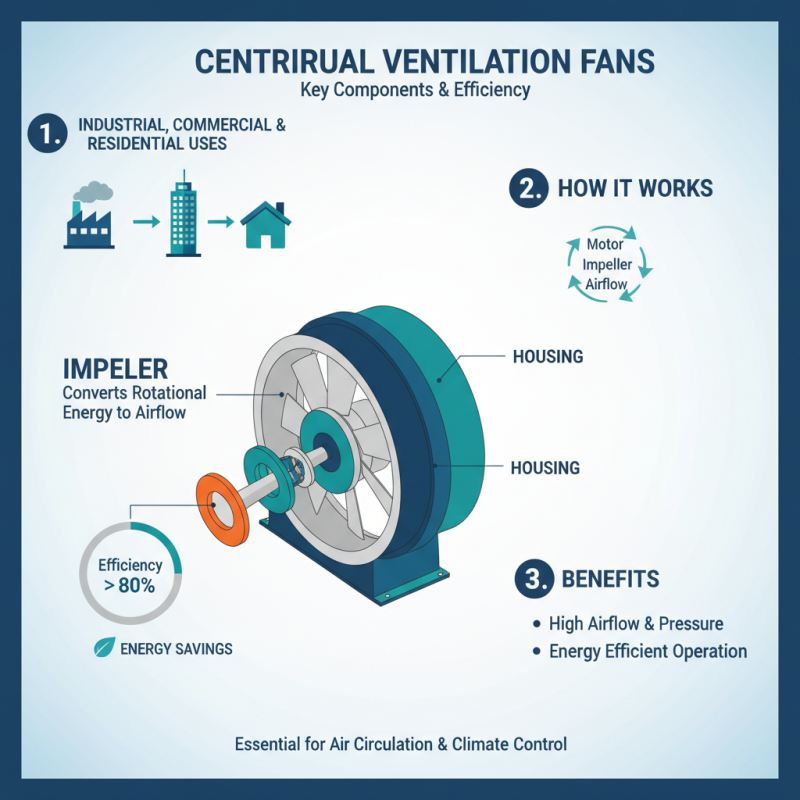

Centrifugal ventilation fans are critical in various applications, including industrial, commercial, and residential settings. Their design relies on key components such as the impeller, housing, and motor. The impeller is crucial; it generates airflow by converting rotational energy into kinetic energy. Research indicates that impellers can operate at efficiencies exceeding 80%, which is significant for energy savings in large facilities.

The motor drives the impeller and is usually an electric type. Selecting the right motor is vital, as it impacts overall fan performance. According to energy efficiency reports, motors can account for up to 60% of a fan's total energy consumption. Many installations have found they can reduce energy usage by 20% simply by upgrading to a more efficient motor.

Housing also plays a pivotal role in noise reduction and airflow efficiency. Better housing designs reduce turbulence, improving fan performance significantly. However, many designs still face challenges. Some models may experience vibration issues, leading to noise and wear. Regular maintenance is essential to address wear and tear, but often, this is overlooked due to budget constraints. These aspects highlight the importance of proper design and regular upkeep in maintaining efficient operation.

Centrifugal ventilation fans play a vital role in various industries. They provide efficient air movement, creating airflow that helps maintain optimal conditions. In manufacturing plants, these fans remove dust and fumes from production areas. This promotes a safer workspace for employees. Additionally, they prevent heat buildup and improve machinery efficiency.

In the HVAC industry, centrifugal fans circulate air in commercial buildings. They help regulate temperature and enhance indoor air quality. These fans are often found in large offices, shopping malls, and schools. They provide comfort and maintain healthy environments. However, improper sizing or installation can lead to inefficiencies and increased energy costs, which is often overlooked.

Centrifugal fans are also essential in the agricultural sector. They aid in ventilation systems for livestock farms. Proper airflow ensures animal comfort and prevents the spread of diseases. Some farms, however, fail to account for varying weather conditions. This oversight may result in inadequate ventilation, affecting animal health. Understanding the specific needs of the environment is crucial for success.

Centrifugal ventilation fans are essential in managing airflow effectively. These fans use a rotating mechanism to draw air in and expel it outward, creating a steady air movement. This design makes them suitable for various applications, from industrial settings to residential use.

One major advantage of centrifugal fans is their ability to handle larger volumes of air. They maintain consistent airflow even against high resistance. This makes them perfect for environments with complex duct systems. Noise reduction is another benefit. Many centrifugal fans operate quietly, enhancing comfort while maintaining efficiency.

**Tip:** When selecting a centrifugal fan, consider the fan's pressure capabilities. Higher static pressure ratings are crucial for systems with long ducts. Also, ensure you factor in installation space; these fans require strategic placement for optimal performance.

The efficiency of these fans can vary. It’s essential to choose a model that fits the specific airflow needs. An ill-fitted fan can result in inadequate airflow or excessive noise. Always evaluate the specifications carefully to avoid these issues.