In today’s industrial landscape, the demand for efficient air handling systems is ever-growing. The Medium Pressure Blower has emerged as a vital solution across various applications. According to a recent industry report from the Blower Manufacturers Association, the medium pressure segment is expanding at a compound annual growth rate of 6% due to its versatility and reliability.

Experts like Dr. Emily Hart, a leading authority on industrial airflow systems, emphasize the importance of selecting the right blower for specific needs. She states, "A Medium Pressure Blower balances efficiency with performance, making it suitable for a range of operations." This balance allows businesses to enhance productivity while maintaining energy efficiency, crucial in today's environmental context.

However, not all applications may require a medium-pressure solution. Some industries might overlook the potential drawbacks, like the initial investment cost. It’s essential to consider whether the benefits align with specific operational needs. Careful assessment is critical. Misjudging requirements could lead to underperformance or excessive expenditure.

Medium pressure blowers are essential in various industries. They efficiently handle air and gases in applications such as wastewater treatment, pneumatic conveying, and cooling systems. Their design allows for stable airflow and consistent pressure, which is crucial for maintaining optimal operations.

One key feature of medium pressure blowers is their ability to manage fluctuations in demand. They adapt smoothly when conditions change, providing reliable performance. The ability to generate medium pressure makes them suitable for handling different materials. In many scenarios, this flexibility proves invaluable, especially in dynamic environments.

Moreover, medium pressure blowers consume less energy compared to high-pressure options. They offer a balance of efficiency and power. Users often notice lower operational costs. However, not all applications will benefit equally. It's important to assess the specific needs of your system carefully. Choosing the right blower requires thought and analysis, as a poor fit can lead to inefficiencies.

Medium pressure blowers play a crucial role in various industries. Their versatility suits many applications, from wastewater treatment to pneumatic conveying. In wastewater treatment plants, they assist in aeration. This process enhances the breakdown of organic matter, improving water quality.

In the food industry, medium pressure blowers are vital for conveying products. They transport granules, powders, and even liquids without damaging the material. Precision is key here, as any inconsistency can affect product quality. Additionally, the chemical industry benefits from these blowers in processes like fluidized bed drying. This application ensures even drying while maintaining material integrity.

However, users must consider efficiency and maintenance. Not every operation needs medium pressure. Sometimes, lower or higher pressure systems might be more suitable. It’s essential to assess specific needs. Investing in the right blower can save costs in the long run. Balancing power requirements with operational needs can be challenging. It requires careful planning and reflection.

Medium pressure blowers offer unique advantages compared to other blower types. They typically operate at pressures ranging from 1 to 10 psi. This range is suitable for various applications, such as material handling and ventilation. Unlike high pressure blowers, medium pressure units achieve efficiency without excessive noise or energy consumption. According to a recent industry report, medium pressure blowers can reduce energy costs by up to 30% compared to their high-pressure counterparts.

When comparing medium pressure blowers to low pressure models, the difference in capacity is significant. Low pressure blowers are often limited in performance, suitable for smaller, less demanding tasks. In industries requiring a balance of efficiency and power, medium pressure blowers shine. They can handle tougher materials and larger volumes. However, some applications may still benefit from the simplicity of low pressure options. It’s crucial to evaluate specific needs carefully.

While medium pressure blowers present many benefits, they also have drawbacks. Installation and maintenance can be more complex than low pressure models. A study indicated that improper installation can lead to a 15% decrease in efficiency. Organizations must consider expertise and resources for optimal use. Understanding these aspects ensures that the right blower type is chosen for the application at hand.

| Type of Blower | Pressure Range (inches H2O) | Flow Rate (CFM) | Efficiency (%) | Common Applications |

|---|---|---|---|---|

| Medium Pressure Blower | 5 - 15 | 100 - 500 | 70 - 85 | Material handling, pneumatic conveying |

| Low Pressure Blower | 0 - 5 | 200 - 800 | 60 - 75 | Aeration, odor control |

| High Pressure Blower | 15 - 30 | 50 - 200 | 80 - 90 | Industrial vacuum, combustion air |

| Regenerative Blower | 10 - 20 | 300 - 1000 | 75 - 88 | Vacuum handling, cooling systems |

| Scroll Blower | 5 - 15 | 150 - 600 | 82 - 95 | Aquaculture, wastewater treatment |

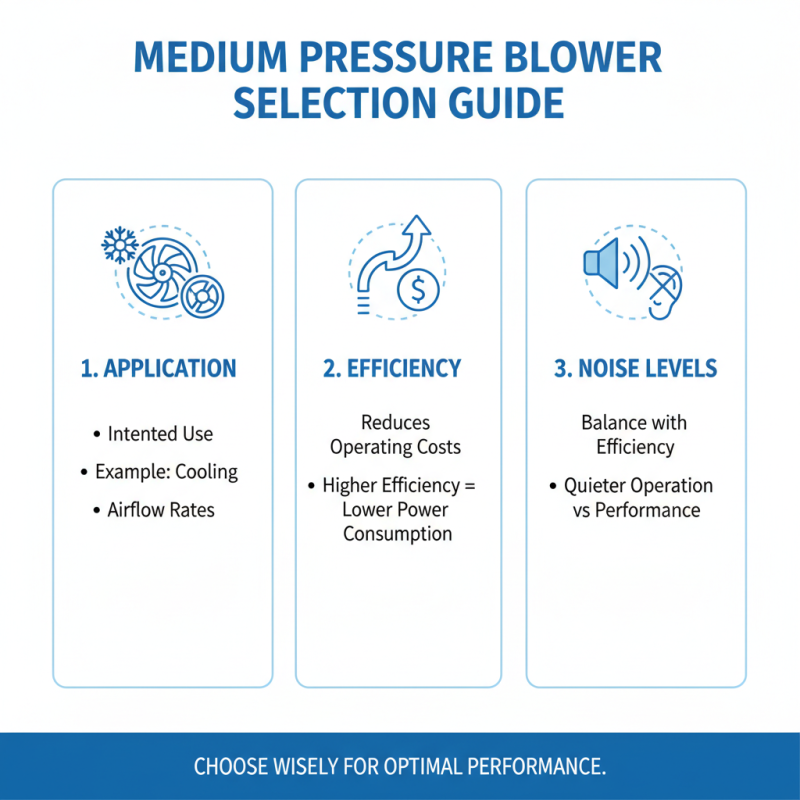

When selecting a medium pressure blower, several factors warrant careful consideration. The intended application plays a significant role. For example, if you use it for cooling, choose a model with suitable airflow rates. The efficiency of the blower is equally important. Higher efficiency can lead to reduced operating costs. However, achieving a balance between efficiency and noise levels can be challenging.

Moreover, sizing the blower correctly is crucial. An oversized blower may lead to wasted energy. Conversely, an undersized model might struggle to meet demands. It’s essential to evaluate the space where the blower will operate. Poor placement can cause inefficiencies, leading to uneven air distribution. Maintenance requirements should also be assessed. Some blowers require frequent servicing, which can be a hassle over time.

Don't forget about compatibility with existing systems. Make sure the new blower integrates well. Sometimes, expectations can exceed reality. It might take trial and error to find the right fit for your needs. Investing time in research is key. Yet, even the best planning does not guarantee perfect results. A deep understanding of your specific application will help in making an informed choice.

Medium pressure blowers are efficient tools for many applications. To keep them running optimally, regular maintenance is crucial. Simple tasks can greatly enhance their performance.

One key tip is to check filters regularly. Clogged filters can restrict airflow. Clean them monthly for peak efficiency.