When selecting the best Regenerative Air Blower for your needs, expert insights can be invaluable. Sarah Thompson, a leading engineer in the air blower industry, states, "Choosing the right blower can significantly impact efficiency." This encapsulates the importance of making an informed decision.

A Regenerative Air Blower operates based on a unique design, providing efficiency and reliability. Your application’s requirements dictate the specifications to consider. Noise levels, airflow rates, and energy consumption are critical factors. Yet, many overlook these details in their selection process.

Mistakes in choosing a Regenerative Air Blower can lead to inefficiencies. For instance, a blower with insufficient capacity may not meet your operational demands. Conversely, an oversized unit can waste energy. In the end, reflecting on these aspects will aid in finding the most suitable blower for your requirements.

Regenerative air blowers are essential in various industries. They operate on a unique principle that allows air to be recycled multiple times. This efficiency is why they have gained popularity compared to traditional blowers. According to recent studies, regenerative blowers can achieve up to 70% energy efficiency in specific applications. It’s vital to understand their basic operation and applications.

These blowers are primarily used in wastewater treatment, pneumatic conveying, and cooling applications. Their ability to generate high pressure with low noise levels makes them suitable for confined spaces. However, not every model meets all needs. Users must consider factors like airflow rates, pressure requirements, and energy consumption. Neglecting these aspects can lead to suboptimal performance and increased operational costs.

Tips: Evaluate your specific requirements before making a decision. Consulting industry reports can provide valuable insights. Regular maintenance is crucial to ensuring longevity and optimal performance. Keep in mind that improper installation may lead to efficiency losses. Always seek expert advice when in doubt. Choosing the right blower involves careful consideration and reflection on your operational needs.

When selecting a regenerative air blower, there are crucial factors to consider. The operational requirements significantly impact your choice. Think about the flow rate you need. This depends on your application. For example, a high flow rate is necessary for large-scale industrial processes. Meanwhile, smaller applications may work with lower flow rates.

Another important aspect to reflect on is the pressure range. Not all blowers can handle high pressure effectively. Evaluate the pressure needs of your system. A mismatched blower can lead to underperformance or damage. It’s vital to analyze the compatibility of the blower with your existing equipment.

Tips: Check the blower's sound levels. Some models may produce excessive noise, which can be disruptive. Look for options with soundproofing features. Additionally, consider energy efficiency. A blower that consumes less power can save costs in the long run.

Lastly, maintenance requirements should not be overlooked. Some blowers need frequent servicing, while others require minimal attention. Reflect on how much time and resources you can dedicate to upkeep. Balancing performance, efficiency, and maintenance is key in finding the right blower for your needs.

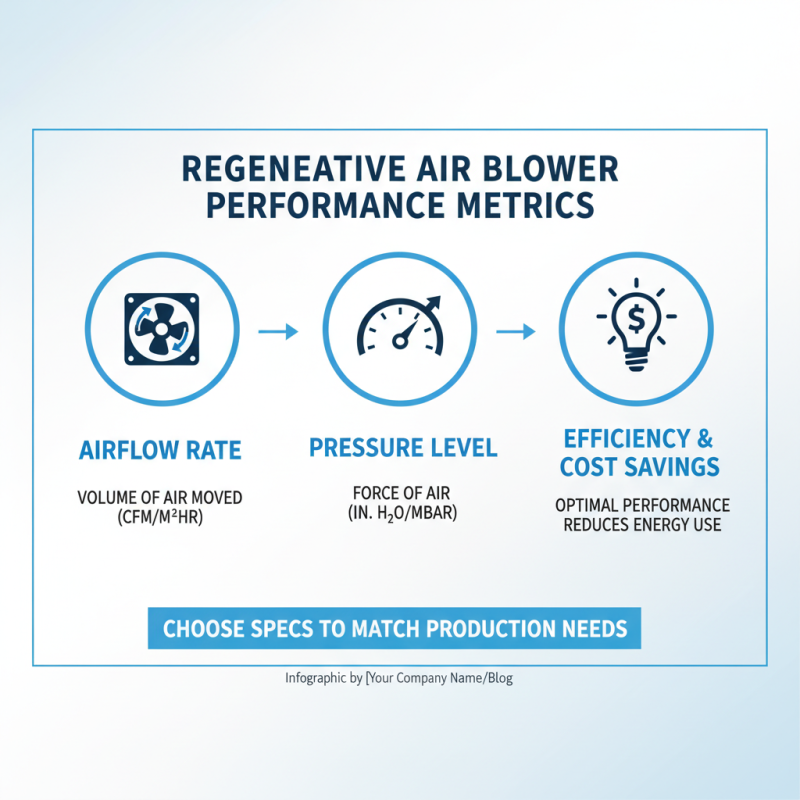

When evaluating regenerative air blowers, understanding performance metrics is crucial. Pay attention to airflow rate and pressure levels. These factors determine the blower's efficiency. Efficient blowers can save energy costs over time. Look for specifications that meet your production needs.

Consider noise levels as well. Some blowers operate quietly, while others are louder. In noisy environments, a low-noise model might be essential for comfort. Analyze what you need in your workspace. Also, think about the size of the blower. It should fit your space without being a hindrance. Larger models offer more power but can be cumbersome.

**Tips:** Always review user feedback on various models. It can provide real-life insights. Consider your budget too. Sometimes, the cheapest option lacks in quality. Make sure to balance cost and performance metrics thoroughly. Reach out directly for assistance if unsure.

When choosing a regenerative air blower, it's critical to compare various brands and models. Each has unique features that cater to different needs. Pay attention to airflow rates and pressure levels. Often, models vary significantly in performance. Some may excel in quiet operation, while others focus on energy efficiency.

Consider the application you have in mind. For instance, if you require a blower for continuous operation, durability becomes essential. Not all models will perform well under heavy use. You might find that some blowers struggle, especially when pushed to their limits. Reading user reviews can shed light on these issues.

Dimensions and installation requirements also matter. Some blowers fit neatly into tight spaces, while others are bulkier. If you lack room, the compact design of specific models could be beneficial.

Don't forget to reflect on maintenance needs, too. Simplicity in maintenance often leads to better long-term performance. A blower may look impressive, but if upkeep is demanding, it could become a burden.

Maintaining your regenerative air blower is essential for its optimal performance. Regular inspections can prevent unexpected breakdowns. Check for any unusual noises. This could indicate a problem. Keep an ear out during operation.

Clean the filters frequently to ensure effective airflow. Clogged filters can hinder performance. A good practice is to establish a cleaning schedule. This might involve checking filters weekly. Don’t underestimate this simple task.

Monitor the lubrication levels in bearings. Insufficient lubrication can lead to excessive wear. If you notice vibrations, it might indicate lubrication issues. Consider keeping a maintenance log. Document what you've checked and when. Reflecting on these tasks can help enhance reliability.