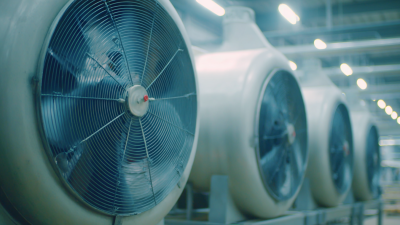

Choosing the right Centrifugal Ventilation Fan is crucial for various applications. These fans are widely utilized in industries such as HVAC, manufacturing, and commercial settings. According to a recent industry report, the global market for ventilation fans is expected to grow by over 5% annually. This growth highlights the increasing need for efficient air movement solutions.

Each application requires a different fan design and performance characteristics. Factors such as air flow rate, static pressure, and energy efficiency come into play. A poorly selected fan can lead to inadequate ventilation, higher energy costs, and maintenance challenges. According to engineers, incorrect fan selection accounts for approximately 30% of operational inefficiencies in industrial setups.

Choosing a Centrifugal Ventilation Fan involves careful consideration. Users often find it overwhelming due to the variety of options available. Key parameters should guide the selection process, yet many overlook specific details. This oversight can lead to systems that do not meet requirements effectively. Understanding these factors is essential for making informed choices.

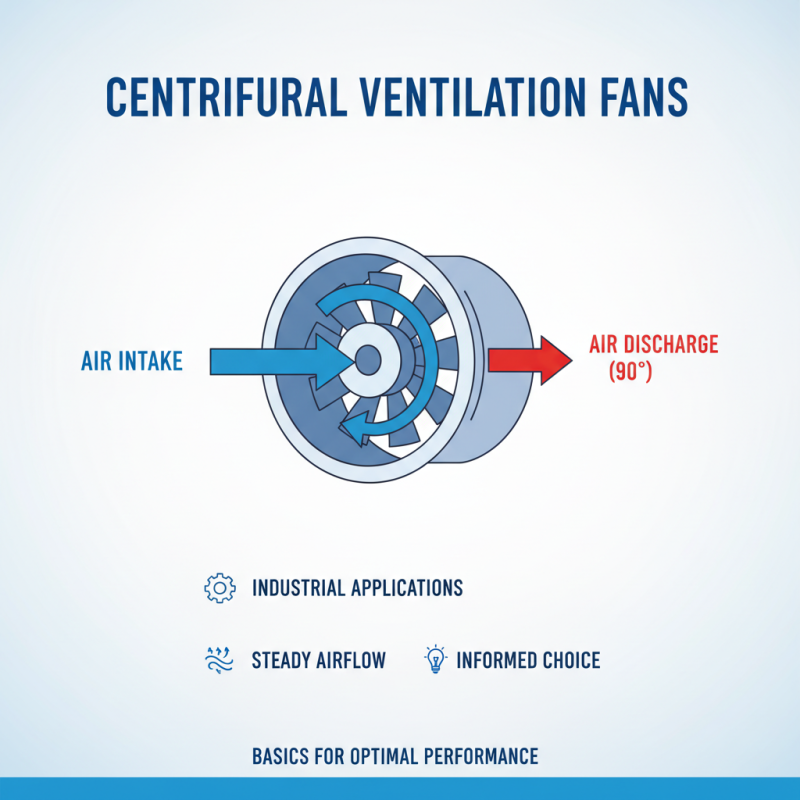

Centrifugal ventilation fans are vital in various industries. They operate by drawing air into the fan and expelling it at a right angle. This design creates a steady airflow, ideal for many applications. Understanding the basics is important for making informed choices.

When choosing a fan, consider the airflow requirements. You need to know how much air you want to move. Not all fans are created equal. Some may not meet your specific needs or efficiency levels. Pay attention to the fan's size and shape. These details impact how it fits into your space.

Efficiency is key, but it's not everything. Noise levels can also be a concern. Some fans can be surprisingly loud. Evaluate the balance between airflow and noise. You may find that an efficient model is not quiet. Remember, your environment matters too. Not every fan works for every application. Make decisions based on your unique requirements.

When selecting a centrifugal ventilation fan, consider several key factors to meet your specific needs. The fan's air flow rate is crucial. It should match the room size and the required ventilation rate. An undersized fan won’t ventilate effectively, while an oversized fan can lead to drafts and increased energy costs.

Another important factor is the fan’s noise level. Some fans operate quietly, while others can be quite loud. If you are installing the fan in a living space, noise could be a significant issue. Measure the sound levels in decibels to find a balance between power and quiet operation.

**Tip:** Always check the fan’s efficiency rating. A fan that operates efficiently will save energy. This choice impacts both your electricity bills and the environment.

Material quality is also critical. A fan made from robust materials can resist wear and increase longevity. Cheaper models may fail sooner, leading to frequent replacements. Consider where the fan will be installed. Factors like humidity and temperature can affect material choice.

**Tip:** Don’t forget about maintenance. Some fans require more maintenance than others. A fan that is easier to clean may save you time and effort in the long run.

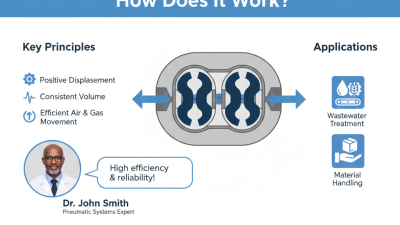

This chart illustrates the key factors to consider when selecting a centrifugal ventilation fan based on application type, efficiency, noise level, and air flow capacity.

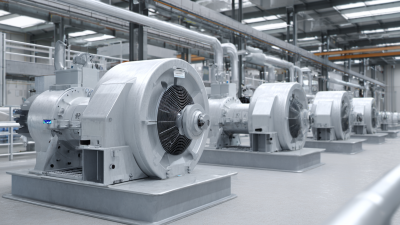

When selecting a centrifugal ventilation fan, performance specifications are crucial.

Focus on airflow capacity, measured in cubic feet per minute (CFM).

A fan with higher CFM moves more air, making it suitable for larger spaces. However, high airflow alone isn’t enough.

Noise levels also matter. A quieter fan is often better for residential areas.

Efficiency ratings play a significant role in the decision-making process.

Look for fans with high Energy Efficiency Ratios (EER).

A fan with a higher EER will consume less electricity for the same airflow, saving you money in the long run.

Energy consumption can sneak up on you. A poorly rated fan may seem cheaper initially but can lead to hefty electricity bills.

When evaluating options, consider installation requirements too. Some fans are easier to install than others.

Complicated setups may not be worth the hassle.

Also, reflect on your specific needs. A fan that performs well in one environment might not suit another.

Make sure to assess the circumstances carefully before making a choice.

Choosing the right centrifugal ventilation fan requires careful consideration of noise levels and airflow needs. Noise can greatly impact comfort in a space. For homes, a fan with a low noise rating is often desirable. In industrial settings, however, how much noise is acceptable may vary. Fast airflow might increase noise. Balancing these factors is key.

Airflow requirements depend on the room's purpose. A living room needs less air than a workshop. You should measure the space accurately. Calculate the needed airflow in cubic feet per minute (CFM). This number helps in selecting the right fan. Overestimating can lead to unnecessary noise. It can also impact energy efficiency.

Reflect on your unique situation. What might work for one space may be inadequate for another? Testing different fans can bring insights. You may discover that even a slightly quieter fan makes a big difference. In some cases, you might need to adjust your choices based on real-world performance. Pay attention to how noise affects daily activities and comfort.

| Fan Size (Inches) | Airflow (CFM) | Static Pressure (Inches WC) | Noise Level (dB) | Energy Efficiency (Watts) |

|---|---|---|---|---|

| 6 | 100 | 0.5 | 60 | 40 |

| 8 | 200 | 0.7 | 65 | 60 |

| 10 | 300 | 1.0 | 70 | 80 |

| 12 | 400 | 1.5 | 75 | 100 |

| 14 | 500 | 2.0 | 80 | 120 |

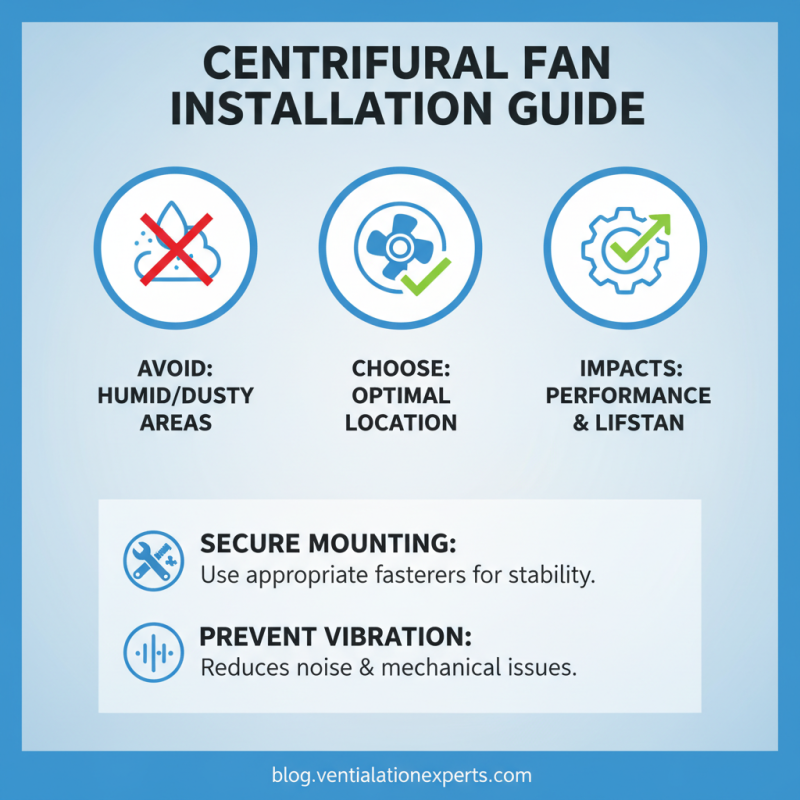

When installing a centrifugal ventilation fan, choose the right location. Avoid areas with high humidity or dust. This choice impacts performance and lifespan. Ensure the fan is mounted securely. Use appropriate fasteners for stability. Vibration can lead to noise and mechanical issues over time.

Routine maintenance is essential for keeping your fan in good condition. Check the motor and blades regularly for wear. Clear any accumulated debris that can hinder airflow. Inspect electrical connections for signs of corrosion. Ignoring these tasks may lead to costly repairs. Ensure that you have a proper maintenance schedule. Even small oversight can result in system failure.

Consider the noise level during operation. Fans can produce varying levels of sound. This factor can affect comfort in nearby areas. Selecting a quieter model may require initial research. But it can save stress later. Testing the fan is vital before finalizing the installation. Minor adjustments can significantly enhance performance. Don't overlook the importance of proper airflow direction. An incorrect setup can lead to inefficiency.