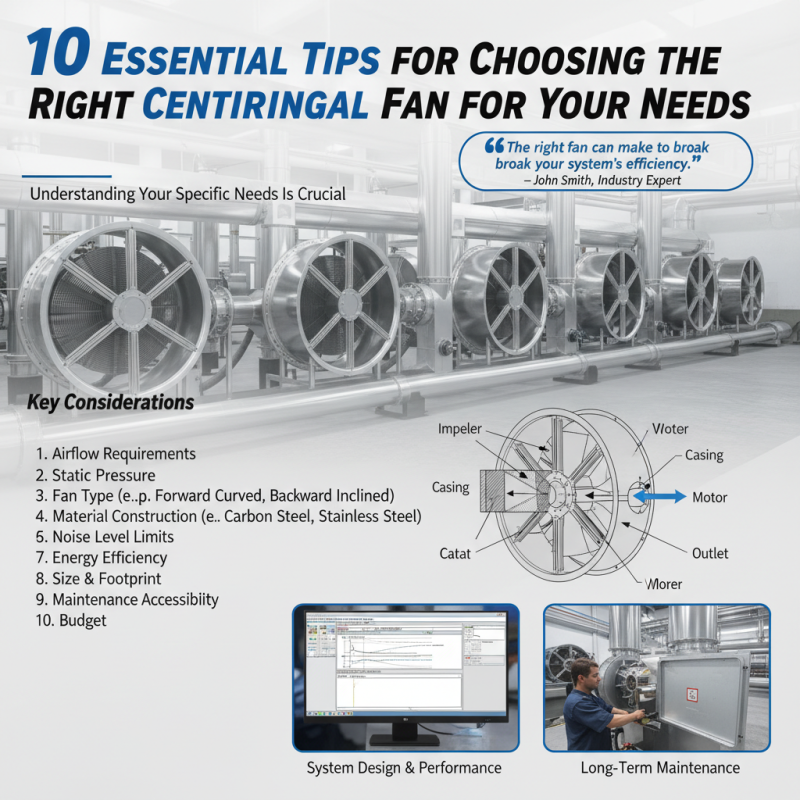

When selecting a centrifugal fan, the choices can be overwhelming. Industry expert John Smith once stated, "The right fan can make or break your system's efficiency." Understanding your specific needs is crucial in making this decision.

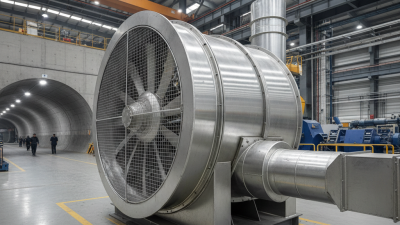

Centrifugal fans are used in various applications, from HVAC systems to industrial processes. The right choice can enhance airflow and energy efficiency. However, many people overlook crucial factors such as noise levels, pressure requirements, and maintenance needs. Each of these aspects can significantly impact the performance of your fan.

It's easy to feel lost in the multitude of options. Not all users know their airflow requirements or the impact of ductwork design. Choosing the wrong centrifugal fan may result in increased energy costs or inefficient operation. Taking the time to assess your needs will help ensure you select the best fan for your situation.

Choosing the right centrifugal fan demands a clear understanding of your specific ventilation needs. Various factors influence performance, including air volume, pressure, and efficiency. The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) emphasizes that proper airflow calculations can improve energy efficiency by 20-30%. This highlights the importance of tailored ventilation solutions.

Before selecting a fan, assess the space where it will be used. Is it a small workshop, or a large industrial facility? The size and layout will affect airflow requirements. A space with high ceilings might require more powerful fans to circulate air effectively. You may overlook potential obstacles, like ductwork or equipment, that could impede airflow. Recognizing these challenges is key to optimizing performance.

Additionally, consider noise levels during operation. Some fans can produce disruptive noise, affecting comfort and productivity. A study by the National Institute of Standards and Technology (NIST) indicates that lower noise levels can significantly enhance work environments. This factor often goes unconsidered until it becomes a problem, warranting reflection on your choices. Overall, a thoughtful approach to centrifugal fan selection not only improves ventilation but also ensures a conducive atmosphere.

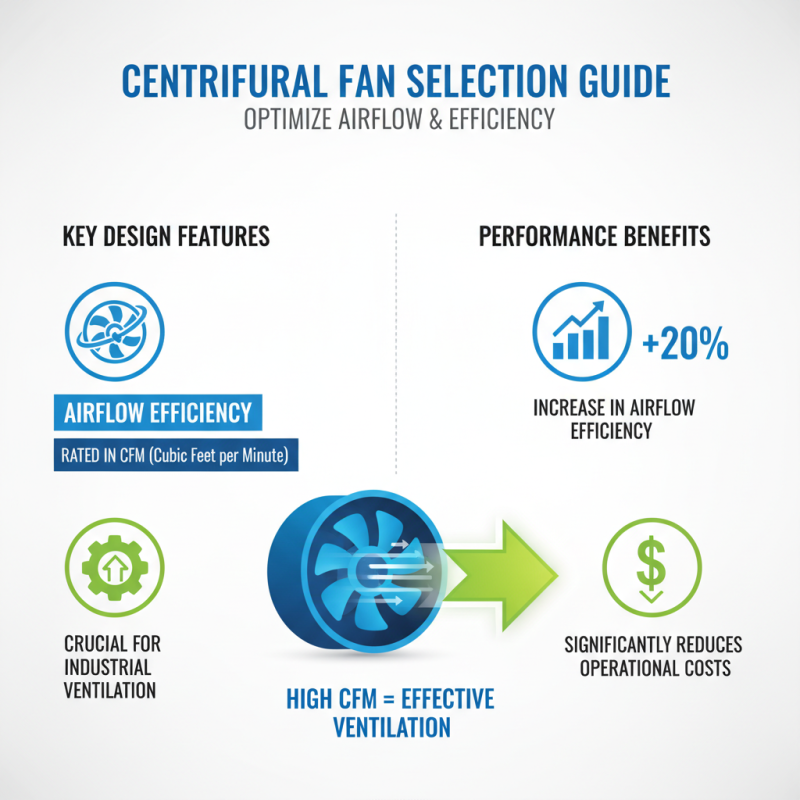

When selecting a centrifugal fan, evaluating performance metrics is crucial. Key factors include airflow capacity, static pressure, and efficiency ratings. Airflow capacity indicates how much air the fan can move. It’s often measured in cubic feet per minute (CFM). Look for a fan that meets your specific airflow needs. A mismatch could lead to poor ventilation.

Static pressure represents resistance in the system. Higher static pressure means the fan must work harder. This can reduce its efficiency. Take time to assess your system’s design. Evaluate ductwork and other elements that impact airflow. Sometimes, a fan with high airflow may not suit your needs due to excessive static pressure. A thorough understanding of these metrics clarifies your selection.

Efficiency ratings, like the Fan Efficiency Grade (FEG), also matter. A higher FEG indicates better performance, which can lead to energy savings. However, balancing performance with cost can be tricky. Fans with high efficiency might have higher upfront costs. Reflect on your long-term energy goals. Sometimes choosing a cheaper, less efficient fan may not save money in the future. Carefully weigh these factors for a more informed decision.

Choosing the right size and capacity for your centrifugal fan is crucial for effective operation. An appropriate fan ensures efficient airflow and energy use. According to industry reports, roughly 70% of fan-related problems stem from improper sizing. Hence, understanding your application is vital.

When selecting a fan, analyze your system's needs. Assess the environment, required airflow, and pressure levels. An under-sized fan might struggle to meet demands, while an over-sized one can waste energy and cause noise issues. Aim for the sweet spot where efficiency meets performance.

Tip: Calculate your required airflow in cubic feet per minute (CFM). It's essential to match CFM to your application. Many engineers use tools and charts to find this balance. Ensure your fan's performance curve aligns with your specific application.

Examining the static pressure requirement is another key step. It affects how much load a fan can handle. A lack of understanding here can lead to performance inconsistencies. Explore different configurations to find the right fit. Remember, what works for one scenario may not suit another. Test configurations if possible. Are you truly getting the airflow you need? Don't overlook these details.

When selecting the right centrifugal fan, understanding key design features is crucial. Look at airflow efficiency. A fan's performance is often rated in CFM (Cubic Feet per Minute). A high CFM ensures effective ventilation in various industrial applications. Reports show that fans with a 20% increase in airflow efficiency can significantly reduce operational costs.

Material selection is another essential feature. Fans can be constructed from steel, aluminum, or high-grade plastics. Each material influences durability, weight, and resistance to corrosion. A recent study indicates that galvanized steel fans typically last 30% longer than their plastic counterparts in harsh environments. Weight also matters. Lightweight fans are easier to install but may not handle high stress as efficiently.

Lastly, consider the noise level. Many industrial fans produce sound levels above 85 dB, which can harm workers' hearing. Many organizations recommend keeping exposure below this threshold for extended periods. Investing in noise-reduction features is not just about comfort; it promotes a healthier work environment. However, achieving a balance between power and noise can be difficult, as powerful fans usually tend to be noisier.

When choosing a centrifugal fan, budget plays a crucial role. It's not just about the initial cost. Long-term savings can often outweigh the upfront price. Think about energy efficiency. Some fans consume more power, raising your monthly bills. A higher efficiency model may cost more initially, but it saves money over time. Calculate your estimated energy costs based on usage.

Maintenance is another factor. Some fans require regular service, adding to your overall expense. Consider models that have fewer moving parts. They typically require less upkeep. You might think a cheap fan is a steal, but hidden costs can make it more expensive. Look for clear maintenance guidelines.

Also, assess the lifespan of each fan option. A durable fan might have a higher price. However, it can last longer and reduce replacement costs. Think about warranty offers too. A solid warranty can protect you from unexpected repairs. Balance these factors against your budget to make a more informed decision.