Choosing the right Electric Side Channel Blower can be challenging. As industry expert Dr. John Smith stated, "In selecting a blower, performance matters, but so do efficiency and reliability." Electric side channel blowers are crucial in various industries for air movement and material handling. They come in different sizes and configurations, making the selection process critical.

Many buyers often overlook efficiency ratings when making their decision. This can lead to increased operational costs and reduced performance. It's easy to focus on just one feature and ignore others. For instance, noise levels are equally important, especially in environments where sound control is necessary. Understanding these details can significantly affect your choice.

There's a tendency to prioritize cost over quality, which can result in regrettable purchases. An Electric Side Channel Blower that seems cheap might not deliver long-term performance. Reflecting on the potential risks and evaluating your specific needs can help in making informed decisions. Ultimately, thorough research is key to finding the perfect Electric Side Channel Blower for your application.

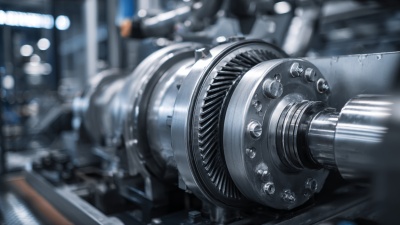

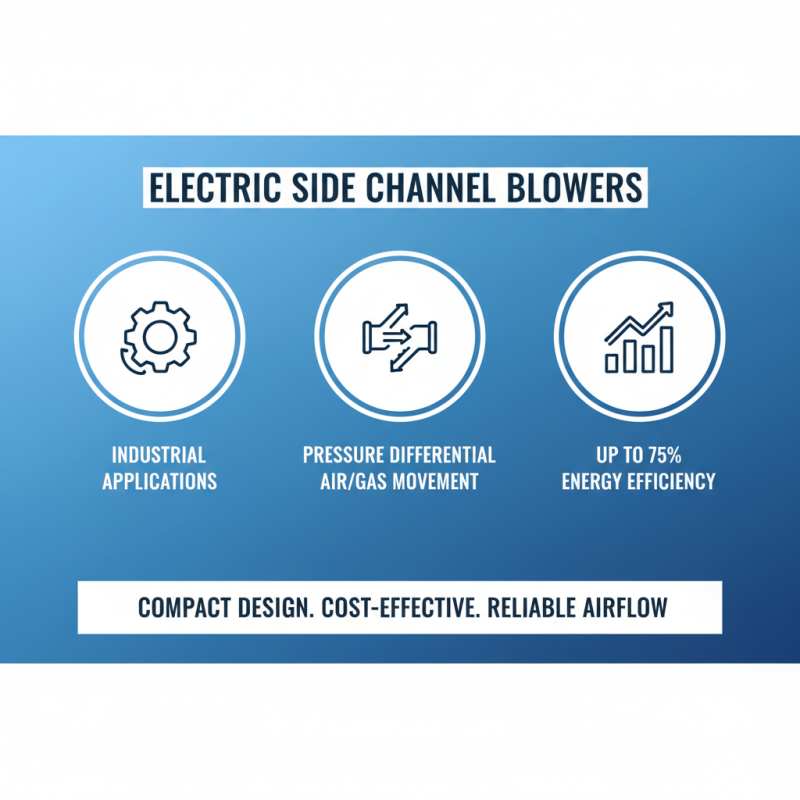

Electric side channel blowers are essential in various industrial applications. These blowers work by creating a pressure differential that moves air or gas. They are known for their efficiency and compact design. According to a recent industry report, their efficiency can reach up to 75% in optimal conditions. This is crucial for minimizing energy costs.

When selecting an electric side channel blower, understanding the basics is vital. You'll want to focus on airflow capacity and pressure ratings. Some blowers may not meet the required specifications. In fact, nearly 30% of buyers report dissatisfaction due to mismatched expectations. Pay close attention to the material and design as well. Using durable materials can extend the blower's lifespan significantly, reducing long-term costs.

Noise levels are another important consideration. Research indicates that noise can impact workplace conditions. Many blowers operate around 70-80 dB, which might be tolerable. However, some environments require quieter options. A blower that's too loud may not be suitable. You may find yourself reflecting on how these factors align with your specific needs. Choosing the right blower involves much more than just cost. It's about finding the perfect balance.

Choosing the right electric side channel blower starts with understanding your application needs. Not all blowers are created equal. Each application has unique requirements that may affect blower selection. Consider the airflow rates you need. Is it high or low? This will dictate the size and power of the blower.

Think about the medium being moved. Will your blower handle air or more dense materials? This detail impacts the construction and durability required. Noise levels also play a role. Some jobs demand quieter operations than others. If noise is a concern, look for blowers designed for lower decibel outputs.

Reflect on the environment where the blower will be used. Will it be in a dusty area or a clean room? This might require sealed models for proper operation. The voltage requirements can also vary based on the setup. Ensure compatibility to prevent operational problems later. Each choice brings its own challenges and trade-offs to consider. Your needs should drive your decision, not just specifications.

| Dimension | Specification | Application Example |

|---|---|---|

| Airflow Rate (m³/h) | 100 - 500 | Vacuum Packaging |

| Pressure (bar) | 0.5 - 3.0 | Aquaculture Aeration |

| Motor Power (kW) | 1.1 - 5.5 | Dust Collection Systems |

| Noise Level (dB) | 60 - 85 | Material Handling |

| Temperature Range (°C) | -20 to +50 | Food Processing |

| Weight (kg) | 10 - 50 | Industrial Cleaning |

| Installation Type | Stationary / Mobile | Portable Blowing Systems |

| Inlet Size (mm) | 50 - 150 | Air Filtration |

| Voltage (V) | 230 / 400 | Pneumatic Conveying |

When evaluating performance specifications for an electric side channel blower, it's vital to understand the basics. Pay attention to airflow specifications, as they define the blower's capacity. A higher airflow rate translates to better performance in many applications. However, don't just look for the highest numbers; consider the specific needs of your setup. Often, efficiency is more crucial than raw capacity.

Noise levels are another critical aspect. Some blowers operate quietly, while others produce significant sound. If your application involves close human interaction, prioritize quieter models. Similarly, check the blower's operating temperature range. It should align with your working environment. A mismatch can lead to performance issues or even equipment failure.

Evaluating power consumption is essential as well. Many users overlook this, thinking it's negligible. But energy efficiency can have a high impact on long-term costs. Ensure the blower you select meets all necessary guidelines. Frustration often arises when trying to fit specifications to expectations. Don't shy away from asking questions or seeking advice. Analyze all options before making a choice.

When selecting an electric side channel blower, understanding noise levels and energy efficiency ratings is vital. Many professionals overlook the noise aspect. According to the American Society of Heating, Refrigerating and Air-Conditioning Engineers, a quieter blower can significantly improve workplace comfort. Blowers generating over 85 dB are often considered disruptive. A unit below this threshold promotes a healthier environment.

Energy efficiency is equally crucial. The U.S. Department of Energy reports that efficient blowers can save up to 30% in operational costs. Look for models with high efficiency ratings. The differences in energy consumption can be stark. For instance, a blower using 500 watts can increase annual electricity costs significantly compared to a model consuming just 350 watts.

While noise and energy use are essential, one must not ignore the specific application needs. The blower’s design and functionality should align with your operational expectations. This requires introspection. Are you prioritizing quiet operation over raw power? Balancing these aspects will lead you to a more suitable choice. The right decision considers all factors rather than focusing solely on one variable.

When selecting an electric side channel blower, maintenance and durability are crucial. Many overlook how important these factors are. Regular upkeep can prevent breakdowns and extend the blower’s lifespan. A blower that requires frequent repairs will quickly become costly.

Look for models with user-friendly maintenance features. Simple access to filters and impellers can save time and effort. Some blowers might look sturdy but fail in tough environments. Consider the materials used. Stainless steel, for example, offers better durability than plastic in harsh conditions.

Pay attention to noise levels as well. A quieter model may involve more complex machinery. Always weigh the benefits against potential issues. Reflect on your specific needs. A blower that performs well in one setting might not be ideal in another. Make an informed decision based on thorough research.