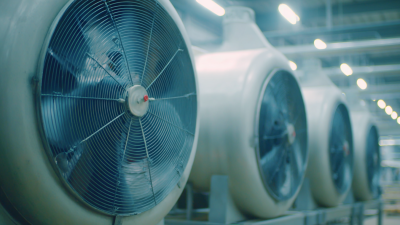

In today's rapidly evolving industrial landscape, the demand for efficient and reliable equipment has never been more critical. Among the various components that ensure optimal performance across multiple sectors, the "Industrial Centrifugal Fan" emerges as a pivotal element. This fan type is essential for providing the necessary airflow and pressure to maintain efficient operations in industries ranging from manufacturing to power generation. According to a report by MarketsandMarkets, the global centrifugal fan market is projected to grow at a CAGR of over 4% from 2020 to 2025, highlighting its increasing significance in industrial applications.

The performance of an industrial operation is directly linked to several factors, including air quality, temperature control, and operational efficiency. A recent study from ResearchAndMarkets notes that effective ventilation systems, including industrial centrifugal fans, can enhance energy savings by up to 30%, thus underscoring their role in sustainable industrial practices. Furthermore, as industries push towards automation and higher production rates, the reliability and performance of industrial fans become essential not only for productivity but also for the longevity of machinery and safety of operations.

With advancements in technology, modern industrial centrifugal fans are designed to be more energy-efficient and capable of handling varying load conditions, making them a crucial investment for businesses focused on optimizing their workflows and reducing operational costs. In light of these trends and data, it is clear that every industry must recognize the integral role of industrial centrifugal fans in achieving sustainable and efficient performance.

Industrial centrifugal fans play a pivotal role in enhancing

process efficiency across various industries. These fans are designed to move air and gases in a controlled

manner, ensuring optimal airflow and pressure. By providing consistent ventilation, they help to maintain

optimal temperatures and prevent overheating in manufacturing processes. This becomes particularly significant

in industries such as chemical processing,

food production, and pharmaceuticals, where

maintaining specific environmental conditions is crucial for product quality and safety.

Moreover, the efficiency of industrial processes can be dramatically improved with the use of centrifugal fans.

They facilitate effective dust and fume extraction, which not only maintains a cleaner

work environment but also adheres to safety and environmental regulations. Additionally, by optimizing air

circulation, these fans contribute to energy savings, reducing operational costs while

enhancing overall productivity. In essence, the integration of industrial centrifugal fans is not merely a

functional choice but a strategic approach to achieving superior performance and

reliability in industrial operations.

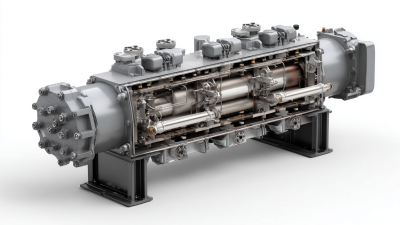

When selecting an industrial centrifugal fan, understanding the key performance indicators (KPIs) relevant to your specific industry is crucial for optimal operational efficiency. Factors such as airflow, static pressure, and efficiency ratings are critical metrics. For example, the American Society of Mechanical Engineers (ASME) outlines that a centrifugal fan designed for high efficiency can reduce energy consumption by up to 30%, translating to significant cost savings for manufacturing plants.

Tips: When assessing airflow requirements, consider the specific characteristics of your application. For instance, the pulp and paper industry typically requires fans that can handle high volumes of air while maintaining consistent pressure. Evaluating noise levels is another essential KPI, particularly in industries like food processing where compliance with health regulations is critical.

Further, industry reports by the Industrial Fan and Blower Association (IFBA) highlight that the right fan selection can positively influence product quality. For applications in the HVAC sector, fans equipped with variable frequency drives can modify speed and improve control over indoor air quality and energy consumption. By focusing on these KPIs when selecting a centrifugal fan, industries can ensure optimal performance and longevity of their equipment.

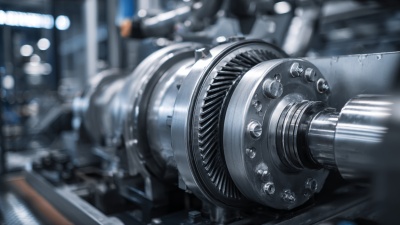

Industrial centrifugal fans play a crucial role in optimizing energy consumption across various sectors. According to the U.S. Department of Energy, fans and blowers account for nearly 20% of electricity consumption in industrial applications. This significant statistic leads to the realization that improving fan efficiency can directly impact operational costs and sustainability initiatives. By using advanced centrifugal fan designs, industries can reduce energy usage by up to 50%, contributing to a more efficient production process and a smaller carbon footprint.

Furthermore, recent studies conducted by the Energy Saving Trust show that upgrading to high-efficiency fans can lead to an annual savings of approximately £1 billion in electricity bills for UK businesses alone. These findings highlight the essential role that industrial fans play in driving energy efficiency while maintaining optimal performance. As industries strive towards sustainability goals, investing in industrial centrifugal fans not only supports compliance with stringent environmental regulations but also enhances overall productivity and profitability.

Centrifugal fans play a crucial role in various industries by providing essential airflow and ventilation. However, in high-usage environments, their performance can degrade over time due to constant operation and potential wear and tear. To increase the lifespan of these fans, regular maintenance is imperative. This includes routinely checking for any signs of wear, ensuring that all components are clean, and promptly addressing any mechanical issues to prevent further damage.

Another important maintenance tip is balancing the fan blades. Imbalances can lead to excessive vibrations, which not only reduce efficiency but can also lead to premature failure of bearings and other parts. Implementing a system for monitoring vibrations and recalibrating the fan as needed will help maintain optimal performance. Additionally, dust and debris can accumulate in the fan system, so keeping the intake and exhaust areas clean will enhance airflow and reduce strain on the motor. By following these maintenance recommendations, industries can ensure their centrifugal fans operate efficiently and effectively over their lifespan.

| Industry | Centrifugal Fan Usage | Maintenance Frequency | Expected Lifespan (Years) | Common Issues |

|---|---|---|---|---|

| Manufacturing | High | Monthly | 10-15 | Dust Accumulation |

| Food Processing | Medium | Every 3 Months | 8-12 | Bearing Wear |

| HVAC | High | Monthly | 15-20 | Vibration Issues |

| Mining | Very High | Weekly | 5-10 | Corrosion |

| Woodworking | Medium | Every 6 Months | 10-15 | Fan Blade Damage |

In today's competitive landscape, various industries must adopt tailored centrifugal fan solutions to enhance their operational efficiency. For example, in the HVAC sector, centrifugal fans play a crucial role in maintaining optimal airflow and temperature control. According to a report by Research and Markets, the global HVAC fan market is projected to reach $12.2 billion by 2025, highlighting a growing demand for effective air management solutions. Customizing centrifugal fans to meet specific airflow requirements not only reduces energy consumption but also improves system reliability.

In the manufacturing sector, centrifugal fans are essential for dust and fume extraction processes. A study by IBISWorld indicates that the industrial ventilation market is expected to reach $6 billion in the U.S. alone by 2024. Utilizing industry-specific centrifugal fans ensures compliance with safety regulations while maximizing performance. For instance, fans designed for high-temperature environments can withstand extreme conditions, providing consistent operation. This tailored approach enhances productivity by reducing downtime and maintenance needs, ultimately leading to considerable cost savings for businesses across various sectors.