Choosing the right equipment for your industrial and commercial needs can be a daunting task, especially when it comes to selecting the appropriate Centrifugal Blower. Centrifugal blowers play a crucial role in various applications, including ventilation, aeration, and material handling. With their ability to move air efficiently and create high-pressure outputs, understanding the key factors that influence your choice becomes essential.

In this guide, we will explore the essential considerations for selecting a Centrifugal Blower that aligns with your specific requirements. From understanding the operational parameters and performance metrics to evaluating energy efficiency and noise levels, each aspect is vital to ensure optimal performance. Whether you are looking to enhance your facility's air circulation or require a solution for environmental controls, making an informed decision about your Centrifugal Blower will result in improved productivity and cost-effectiveness.

Join us as we delve deeper into the features and specifications that matter most, equipping you with the knowledge needed to make an informed choice that will serve your needs effectively and efficiently.

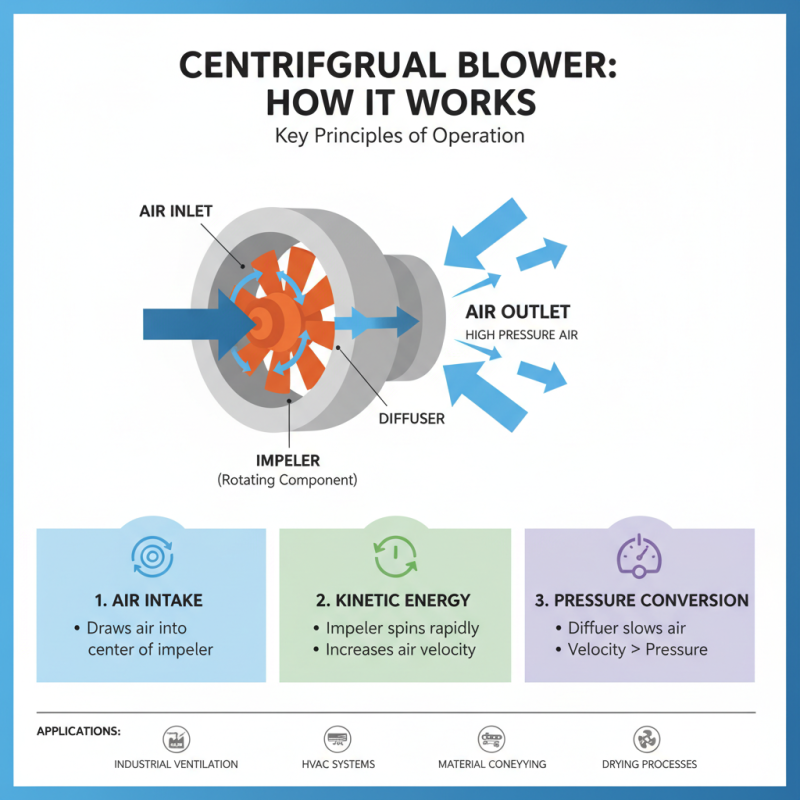

Centrifugal blowers are vital components in various industrial applications, designed to move air or gases through a system. Their operation is based on a few key principles that govern their efficiency and performance. At the heart of a centrifugal blower is an impeller, a rotating component that draws in air at the inlet and expels it at high pressure. The kinetic energy generated by the spinning impeller is converted into potential energy as the air moves outward through a diffuser, which helps to increase the velocity and pressure of the airflow.

Understanding the mechanisms behind centrifugal blowers is essential for selecting the right model for specific needs. These blowers operate under the principles of centrifugal force and aerodynamic efficiency. The design of the impeller, along with the blower casing, significantly affects the airflow characteristics, such as volume and pressure rise. Additionally, factors like the speed of the impeller and the diameter play a crucial role in determining the blower's capacity and energy consumption. By grasping these fundamental concepts, users can better assess their requirements and choose a blower that aligns with their operational objectives while maximizing efficiency.

When selecting a centrifugal blower for specific applications, it is crucial to understand the different types available and their unique characteristics. Centrifugal blowers can be categorized based on their design, airflow volume, and pressure capabilities. Radial blowers, for instance, are designed for moderate pressure applications, offering efficient airflow for ventilation and material handling. In contrast, mixed flow blowers bridge the gap between axial and radial types, providing a versatile solution for operations requiring both high flow rates and moderate pressure, making them suitable for HVAC systems and industrial processes.

According to recent industry reports, the global centrifugal blower market is projected to grow at a compound annual growth rate (CAGR) of approximately 5.8% from 2021 to 2028. This growth is driven by the increasing demand for energy-efficient and sustainable solutions across various sectors, including manufacturing and water treatment. Industries focusing on air pollution control and the management of airborne particles are notably prioritizing centrifugal blowers due to their effectiveness in ensuring clean and efficient airflow.

When selecting the best type for your application, consider factors such as pressure requirements, airflow volume, efficiency, and the specific environmental conditions to achieve optimal performance and longevity of the blower system.

When selecting a centrifugal blower, understanding the factors that influence performance is crucial. Airflow, pressure, and efficiency are key variables that determine how well the blower will meet your specific requirements. According to recent industry studies, optimal airflow can reduce energy costs significantly, with efficient blowers yielding savings of up to 15% when properly matched to their application. It's essential to analyze the required airflow rates and pressure levels for your processes to ensure that the blower you choose can handle the demands without compromising performance.

Pressure is another critical element that influences blower selection. The blower's ability to generate sufficient static pressure is vital for applications that require overcoming resistance in ducts or other systems. Industry data shows that a blower operating at the right pressure can enhance system performance while minimizing wear and tear on mechanical components. It's advisable to assess the pressure requirements early in the decision-making process to avoid costly miscalculations.

Tips: Always review the blower's efficiency rating, as higher efficiency not only reduces operational costs but also extends the lifespan of the equipment. Additionally, consider your application's unique characteristics, such as variation in airflow or pressure demands, which may necessitate a more adaptable blower choice. Regular maintenance is essential to ensure that the blower continues to operate at peak performance over its lifespan.

When selecting a centrifugal blower, material and design considerations are crucial for ensuring durability and longevity. The choice of materials directly affects the blower's ability to withstand various operating conditions, including temperature fluctuations, humidity, and exposure to corrosive substances. Metals such as stainless steel or specially coated alloys provide excellent resistance to corrosion and wear, making them suitable for harsh environments. On the other hand, composite materials and plastics can offer lightweight alternatives while maintaining sufficient strength for less demanding applications.

Design features also play a significant role in determining the lifespan of a centrifugal blower. Engineers often focus on elements such as impeller geometry, housing shape, and airflow dynamics to enhance efficiency and reduce stress on components. A well-optimized design minimizes wear and tear, which can lead to increased maintenance needs and downtime. Additionally, features such as vibration dampening and noise reduction should be considered, as these can contribute to the overall performance and user comfort of the blower. With the right combination of materials and design, a centrifugal blower can provide reliable service for many years, meeting the specific needs of various applications.

Proper maintenance of centrifugal blowers is crucial for ensuring optimal performance and extending their lifespan. According to the American Society of Mechanical Engineers (ASME), regular maintenance checks can improve equipment efficiency by up to 20%. This efficiency translates directly into energy savings and reduced operational costs. Essential maintenance tasks include routine inspections, lubrication of moving parts, and ensuring that air filters are clean and free from blockages. By implementing a maintenance schedule that adheres to the manufacturer’s guidelines, users can minimize the risk of unexpected breakdowns and enhance the overall reliability of the blower.

Additionally, monitoring the operating environment is vital in maintaining blowers. Factors such as temperature, humidity, and overall air quality can significantly affect performance. A report from the Environmental Protection Agency (EPA) highlights that blowers operating in less than optimal environmental conditions can experience up to a 15% decline in performance efficiency. Keeping the working area clean and ensuring that intake areas are free from debris not only protects internal components but also promotes a healthier operational environment. By prioritizing these maintenance tips, users can ensure that their centrifugal blowers perform reliably and efficiently over their intended lifespan.

| Dimension | Specification | Maintenance Tip | Expected Lifespan |

|---|---|---|---|

| Airflow Rate | 1000 - 5000 CFM | Regularly clean air intake filters | 10 - 15 years |

| Motor Power | 5 - 50 HP | Check motor bearings for lubrication | 15 - 20 years |

| Noise Level | 60 - 90 dBA | Install vibration dampeners to minimize noise | 5 - 10 years |

| Operating Temperature | -20 °C to 60 °C | Ensure adequate ventilation | 10 - 15 years |