In recent years, the industrial sector has witnessed a significant surge in the applications of High Pressure Ring Blowers, as these devices are known for their efficiency and versatility. According to a report published by MarketsandMarkets, the global air blower market is projected to reach USD 8.6 billion by 2024, growing at a CAGR of 4.7% during the forecast period. This growth is largely driven by the increasing demand for energy-efficient and compact blowers in various industries, including wastewater treatment, packaging, and pneumatic conveying systems.

High Pressure Ring Blowers are particularly valued for their ability to generate high airflow at elevated pressures, making them ideal for various applications where consistent and powerful air delivery is crucial. A recent survey from Research and Markets highlights that the adoption of High Pressure Ring Blowers in the wastewater treatment industry alone is expected to grow significantly, as municipalities seek more efficient ways to handle aeration processes. Furthermore, their implementation in the packaging industry has not only optimized production lines but also considerably reduced operational costs.

In this article, we will explore the top ten applications of High Pressure Ring Blowers that are not only transforming industries but also enhancing productivity and operational efficiency across the board. Understanding these applications is essential for professionals looking to leverage this technology for improved performance and sustainability in their operations.

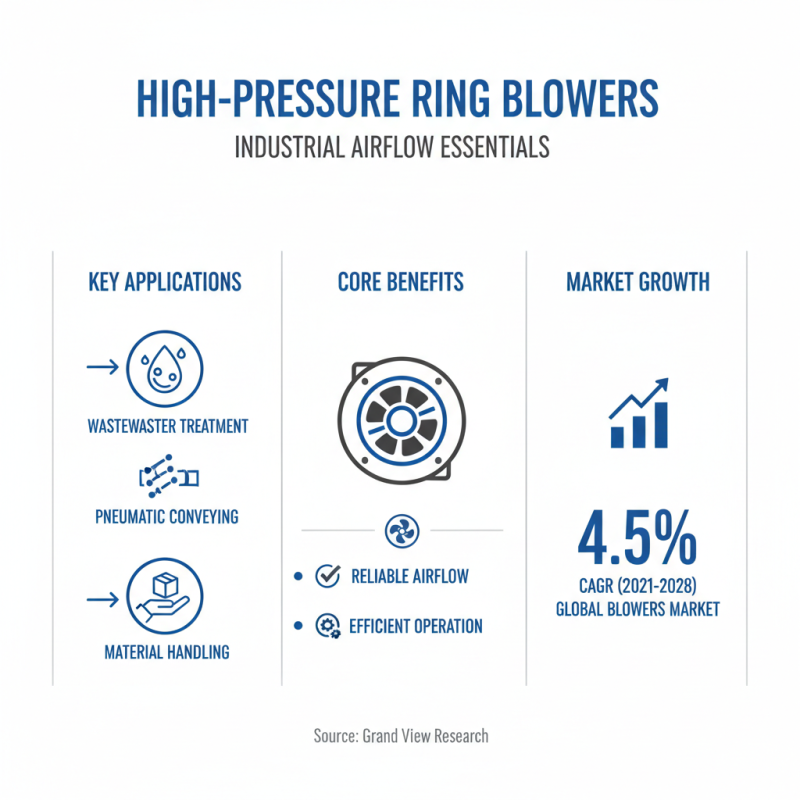

High pressure ring blowers are essential components in numerous industrial applications, providing reliable airflow and efficient operation. These devices are engineered to deliver high pressure output, making them invaluable in sectors such as wastewater treatment, pneumatic conveying, and material handling. According to a market research report by Grand View Research, the global market for blowers, including high pressure variants, is expected to grow at a CAGR of 4.5% from 2021 to 2028, reflecting the increasing demand for efficient pneumatic systems across diverse industries.

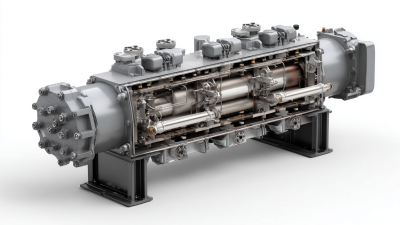

The key features of high pressure ring blowers include their robust construction, energy efficiency, and low maintenance requirements. With the ability to generate pressure levels ranging from 0.5 to 1.5 bar, these blowers can effectively transfer gases and materials, ensuring consistent operational performance. The design of ring blowers allows for a compact form factor, making them suitable for confined spaces while still providing optimal airflow. Furthermore, according to a report from Research and Markets, the adoption of high pressure ring blowers is on the rise due to their ability to reduce operational costs by up to 20% compared to conventional blower systems. Their versatility and cost-effectiveness make them a preferable choice in various applications, driving innovation in many industries.

High pressure ring blowers play a crucial role in various industrial applications, particularly in manufacturing processes. These blowers are essential for creating high airflow and pressure in systems that require efficient air movement. In industries such as plastics, textiles, and food processing, these blowers help optimize production flows, facilitate drying processes, and manage waste efficiently. For instance, in the textile industry, high pressure ring blowers assist in the drying of fabrics, ensuring that products reach market readiness quickly and with quality intact.

When considering the implementation of high pressure ring blowers in your manufacturing setup, it's essential to focus on a few key tips. Firstly, assess the specific airflow and pressure requirements of your process to choose the right blower configuration. Secondly, ensure proper maintenance routines are in place, which can extend the lifespan of the blower and maintain optimal performance. Regularly check for any leaks or blockages that could hinder airflow efficiency.

Moreover, integrating high pressure ring blowers into your systems can also improve energy efficiency. By optimizing the blower's operation to match the production needs, you can significantly reduce energy consumption while enhancing productivity. This balance between performance and energy use is essential for maintaining a competitive edge in today’s manufacturing landscape.

| Application Area | Description | Pressure Range (Psi) | Industries |

|---|---|---|---|

| Pneumatic Conveying | Used for the transport of bulk materials in manufacturing processes. | 5 - 15 Psi | Food, Pharmaceuticals |

| Wastewater Treatment | Utilized for aeration and mixing in treatment processes. | 10 - 20 Psi | Environmental Engineering |

| Printing Industry | Aid in the drying and cooling of printed materials. | 8 - 12 Psi | Printing, Packaging |

| Food Processing | Used in processes like drying, cooling, and mixing of food products. | 7 - 15 Psi | Food Industry |

| Packaging Machinery | Provides vacuum and pressure for shaping and sealing packages. | 5 - 18 Psi | Packaging, Logistics |

| Textile Industry | Used for the cleaning and blowing off particles from fabrics. | 6 - 14 Psi | Textiles, Apparel |

| Chemical Processing | Aids in the mixing and transfer of chemical materials. | 10 - 25 Psi | Chemicals, Petrochemicals |

| Electronics Manufacturing | Used for cleaning components and handling careful assemblies. | 8 - 16 Psi | Electronics, Semiconductors |

| Pharmaceuticals | Used in production processes requiring sterile environments. | 5 - 12 Psi | Pharmaceutical Industry |

High pressure ring blowers play a pivotal role in wastewater treatment processes, providing essential aeration and material handling capabilities. These blowers are known for their ability to generate high airflow and pressure with energy efficiency, making them ideal for various applications in the treatment of wastewater. According to a report by the Water Environment Federation, the efficient management of aeration systems in wastewater treatment plants can reduce energy use by as much as 30%, underscoring the importance of selecting the right equipment.

In the aeration process, high pressure ring blowers supply the air necessary for microorganisms to thrive, facilitating the breakdown of organic matter. The blowers can also support processes such as flotation and filtration, which are essential for achieving compliance with environmental standards. A study by the Global Water Intelligence highlights that approximately 60% of operating costs in wastewater treatment facilities are attributed to energy consumption, emphasizing the significant impact that efficient blower systems have on operational expenditures. Implementing modern high pressure ring blowers not only enhances the efficiency of treatment processes but also contributes to sustainable practices by minimizing energy waste and optimizing resource utilization.

High pressure ring blowers play a crucial role in aquaculture systems, providing necessary aeration and circulation for aquatic life. The ability to deliver consistent and high-volume air supply is vital in maintaining optimal water quality, promoting fish health, and supporting efficient growth rates. According to a report from the Aquaculture Engineering Society, effective aeration increases fish productivity by up to 30%, underscoring the importance of reliable air management in these environments.

One of the key benefits of utilizing high pressure ring blowers is their energy efficiency. Studies have shown that these blowers can reduce energy consumption by 20% compared to traditional aeration methods. This not only lowers operational costs but also minimizes the carbon footprint of aquaculture farms. Additionally, the compact design of high pressure ring blowers allows for easier installation and maintenance, making them a preferred choice for many aquaculture operators.

**Tip:** Regular maintenance of high pressure ring blowers can prevent unexpected downtime. Keeping an eye on air intake filters and ensuring the blower is free of obstructions can enhance its performance and longevity.

Furthermore, high pressure ring blowers facilitate the use of various aeration techniques, such as bubble diffusers and surface aerators, leading to improved oxygen transfer rates. A robust aeration system leads to more uniform distribution of oxygen, which is essential for the health of aquatic species. According to industry data, optimal oxygen levels can lead to a 15% increase in growth rates for various fish species, emphasizing the significance of effective aeration in aquaculture.

**Tip:** Consider implementing a monitoring system to frequently check oxygen levels and adjust the blower settings accordingly, ensuring that your aquatic environment remains optimal for growth.

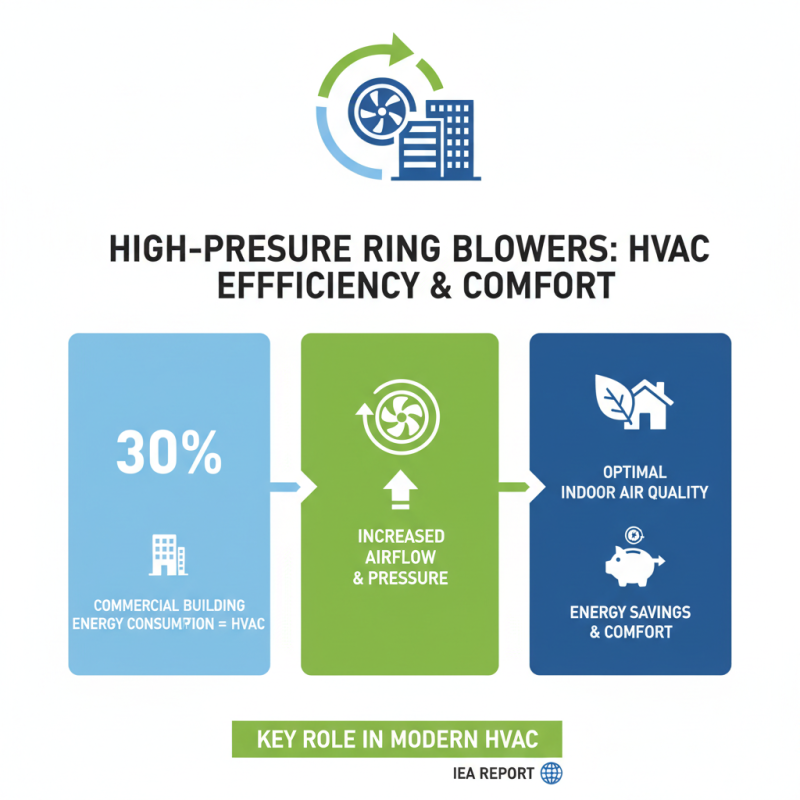

High pressure ring blowers are increasingly recognized for their critical role in HVAC systems, thanks to their ability to efficiently move large volumes of air at high pressure. According to a report by the International Energy Agency, HVAC systems account for around 30% of the energy consumed in commercial buildings. High pressure ring blowers enhance these systems by improving air circulation and maintaining optimal indoor air quality, which is essential for energy savings and occupant comfort.

One of the innovative applications of high pressure ring blowers in HVAC systems is their integration into ventilation systems. These blowers facilitate effective exhaust ventilation in commercial kitchens, industrial facilities, and large-scale HVAC applications. A recent study by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) highlighted that using high pressure blowers can increase energy efficiency by up to 25%, as they allow for a more consistent and powerful airflow. Additionally, their compact design enables easier installation and retrofitting in existing systems, making them a cost-effective solution for enhancing air management.

Furthermore, high pressure ring blowers are not only limited to traditional ventilation but also play a vital role in advanced HVAC systems, such as those utilizing heat recovery and air purification technologies. By efficiently delivering required airflow rates, they support the functionality of heat exchangers and air filters, ensuring that indoor environments remain healthy and comfortable. A report by the U.S. Department of Energy emphasizes that improving air distribution with high pressure blowers can lead to significant reductions in both operational costs and greenhouse gas emissions, highlighting their importance in sustainable building practices.