In today’s fast-paced industrial landscape, optimizing energy consumption is paramount for both cost savings and sustainable operations. One effective solution gaining attention is the Ring Type Air Blower, which offers a remarkable reduction in energy use, boasting up to a 30% decrease in consumption across various applications. This innovative technology not only enhances efficiency but also contributes to lower operational costs and a reduced carbon footprint, making it an attractive option for industries looking to improve their performance while being environmentally responsible. In this guide, we will explore the principles of Ring Type Air Blowers, their operational advantages, and best practices for implementation, illustrating how they can be a game-changer for facilities aiming to maximize efficiency and enhance overall production capabilities.

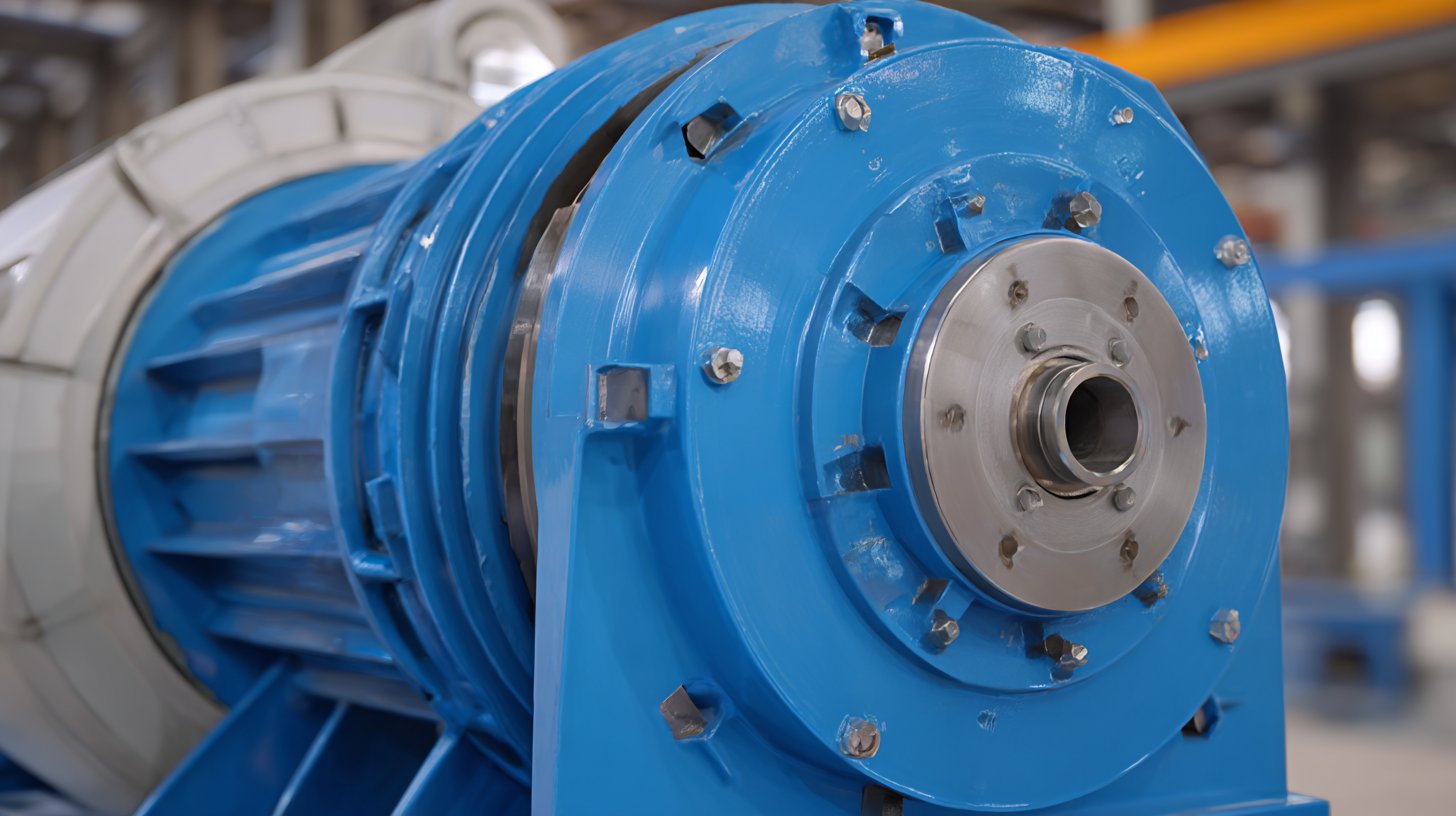

Ring type air blowers are an innovative solution designed to enhance efficiency in various industrial applications. These blowers operate on the principle of ring formation, which optimizes the airflow dynamics within the system. According to a report from the Industrial Blowers Association, the unique design of ring type air blowers allows for lower operating speeds while maintaining a high volume of air displacement. This results in significant reductions in energy consumption, often cited at approximately 30% compared to traditional blower systems.

The functionality of ring type air blowers is further amplified by their ability to minimize noise levels and vibration, making them ideal for environments where sound pollution is a concern. Statistics from the Energy Efficiency Council indicate that industries implementing ring type blowers not only achieve energy savings but also experience a decrease in maintenance costs, as these systems have fewer moving parts and are less prone to wear and tear. The combination of advanced design and operational efficiency positions ring type air blowers as a vital component in the quest for sustainable industrial practices.

| Application Area | Energy Consumption Before (kW) | Energy Consumption After (kW) | Energy Savings (%) | Typical Use Case |

|---|---|---|---|---|

| Material Handling | 100 | 70 | 30% | Conveying powders and granules |

| Cooling Systems | 80 | 56 | 30% | Process cooling |

| Wastewater Treatment | 120 | 84 | 30% | Aeration processes |

| Dust Control | 90 | 63 | 30% | Industrial dust suppression |

Energy efficiency is a critical consideration in modern industrial applications, where the costs of energy consumption can significantly impact a company’s bottom line. According to a report by the U.S. Department of Energy, fans and blowers account for nearly 20% of industrial energy use, highlighting the importance of optimizing air movement solutions. Among these solutions, ring type air blowers have emerged as a game-changer, enhancing operational efficiency while reducing energy costs by up to 30%.

The technology behind ring type air blowers allows for a high-volume air output with minimal power input. This efficiency stems from their design, which provides a continuous flow of air without the need for complex mechanisms, resulting in lower friction losses and less energy waste. A study conducted by the European Commission indicated that by integrating such efficient air movement technologies, manufacturers could lower their energy expenses significantly. In industries where air movement is essential—such as food processing, chemical production, and HVAC systems—adopting ring type air blowers not only conserves energy but also contributes to a more sustainable operational model.

In the realm of industrial applications, the choice between ring type air blowers and traditional blower systems can significantly impact energy efficiency and operational costs. Ring type air blowers utilize a unique design that facilitates a more streamlined airflow, reducing turbulence and enhancing pressure delivery. This is in stark contrast to traditional blowers, which often rely on more complex mechanisms that can lead to inefficiencies and increased energy consumption. Studies indicate that ring type air blowers can cut energy usage by up to 30%, presenting a compelling case for industries looking to minimize operational expenses while maximizing output.

The comparative analysis between these two systems reveals not only energy savings but also improvements in performance and maintenance. While traditional blower systems may require frequent upkeep due to their intricate moving parts, ring type blowers boast fewer components, translating to reduced maintenance requirements and longer operational lifespans. Additionally, the simplicity of the ring type design allows for easier integration into existing systems, ensuring a smoother transition for facilities aiming to enhance productivity without compromising reliability. Ultimately, the shift toward ring type air blowers represents a strategic advantage for industries prioritizing energy efficiency and effective resource management.

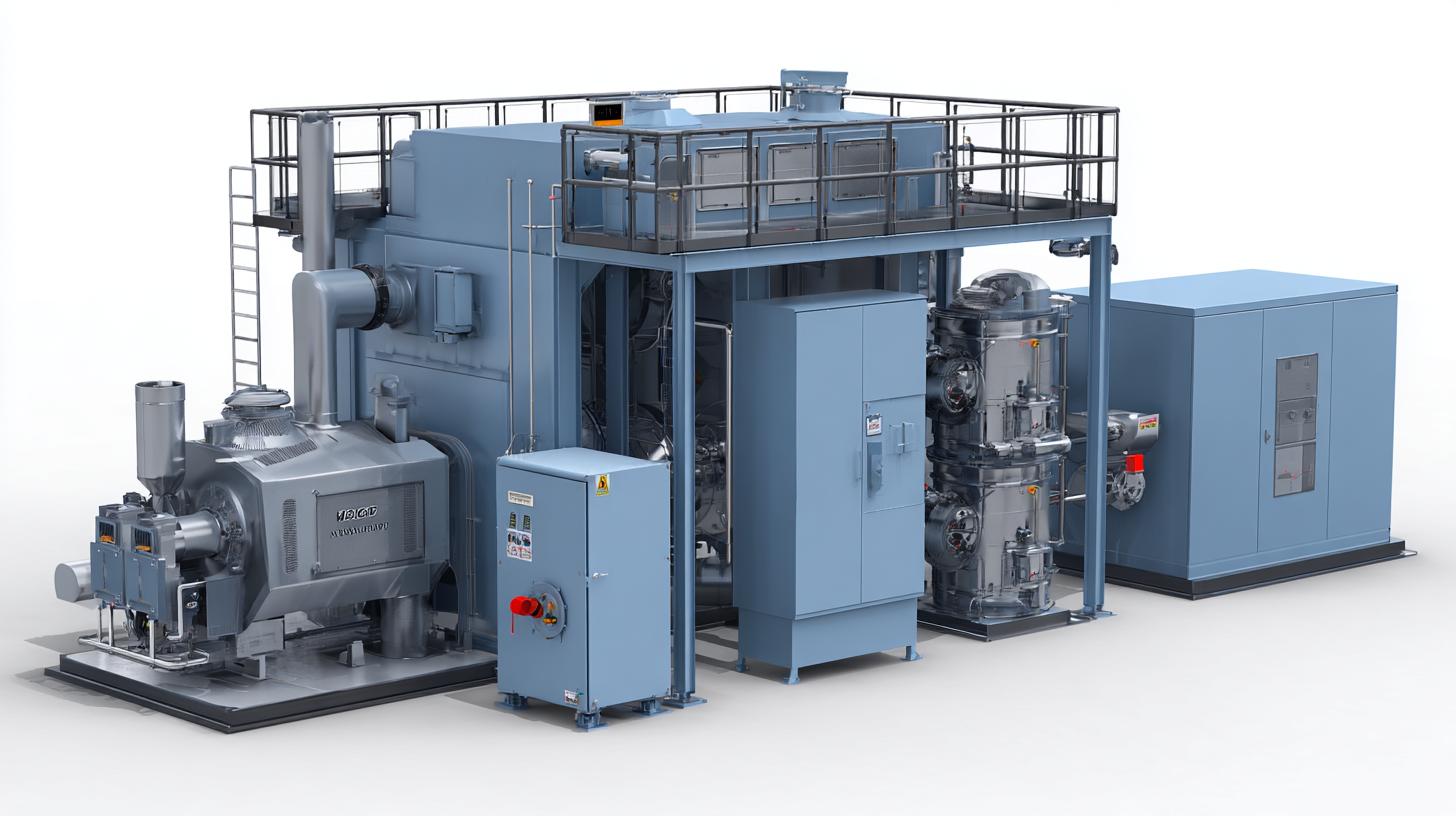

In recent years, the push for energy efficiency in industrial applications has led to significant advancements in air blowers, particularly ring type air blowers. According to a report by the U.S. Department of Energy, these specialized blowers can save up to 30% in energy consumption compared to traditional centrifugal blowers. This remarkable efficiency not only reduces operational costs but also supports sustainability initiatives across various industries.

Real-world case studies illustrate the effectiveness of ring type blowers in action. For instance, a manufacturing facility that implemented ring type air blowers reported a decrease in energy costs by nearly $50,000 annually, alongside a reduction in their carbon footprint. Furthermore, data from the Industrial Energy Efficiency Program shows that upgrading to ring type technology has helped numerous manufacturers streamline their processes, enhance performance, and achieve significant energy savings, leading to higher production rates and less downtime.

Innovations in air blower technology are paving the way for a more efficient and sustainable future in industrial applications. With the increasing focus on energy conservation, manufacturers are continuously exploring advanced materials and designs that optimize airflow while minimizing energy usage. Recent developments have seen the introduction of smart sensors and IoT integration, allowing for real-time monitoring and management of air blower systems, which enhances operational efficiency and reduces waste.

Moreover, emerging trends in eco-friendly design have led to the creation of quieter, more compact air blowers that deliver powerful performance without compromising on environmental standards. These innovations not only contribute to significant energy savings—up to 30%—but also align with global sustainability goals, making them an attractive option for industries aiming to reduce their carbon footprint. As technology continues to evolve, we can expect even more groundbreaking solutions that will further enhance the capabilities of air blowers, solidifying their vital role in efficient industrial operations.

This chart illustrates the energy consumption comparison between traditional air blowers and ring type air blowers. The data shows that ring type air blowers reduce energy consumption by approximately 30%, demonstrating their effectiveness in industrial applications.