A Roots Blower is a unique mechanical device. It is widely used in various industrial applications. These blowers create a steady flow of air or gas. They work on a simple principle involving two rotors.

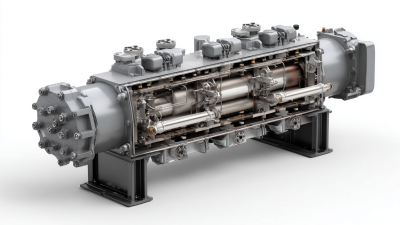

The design of a Roots Blower includes two lobes. These lobes rotate in opposite directions. This movement traps air and pushes it through the system. The efficiency of this device is impressive. However, not all users understand how it operates.

Understanding a Roots Blower requires examining its components. The rotors must be balanced for optimal performance. Users often overlook maintenance needs. Regular checks are essential to ensure longevity. Failure to do so can lead to breakdowns and inefficiency. Exploring these aspects can enhance operational knowledge significantly.

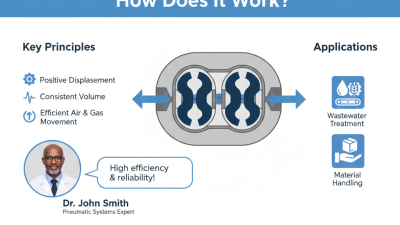

A Roots blower is a mechanical device that moves air or gas. It is widely used across industries, especially in wastewater treatment, pneumatic conveying, and chemical processing. These blowers operate on the positive displacement principle. They capture a fixed volume of air and push it into the system. This process leads to efficient air/gas delivery.

The primary functions of a Roots blower include aeration, conveying, and vacuum generation. According to industry reports, the global roots blower market is projected to grow at a CAGR of 5.3% from 2020 to 2026. This growth indicates the increasing demand in various sectors. In wastewater treatment, they help maintain optimal oxygen levels for bacteria. In food processing, they assist in transferring powders and granules smoothly.

However, there are challenges. The need for regular maintenance can be a downside. Operators must monitor pressure and temperature to ensure efficiency. Over time, wear and tear can affect performance. Effective management is essential to prevent costly downtimes. Many users may overlook the importance of proper ventilation, leading to suboptimal results. This calls for a reassessment of operational practices.

A Roots blower is a type of positive displacement compressor. It operates based on a simple yet effective principle. Two rotors spin in opposite directions within a casing. As they turn, they create a sealed chamber that moves air from the inlet to the discharge.

The key to its operation lies in the design of the rotors. They usually have lobes that mesh together but do not touch. This design minimizes wear and maximizes efficiency. When the rotors spin, they trap air and push it into the output side. The design allows for a steady, reliable airflow. However, there might be slight inefficiencies that arise from backflow, particularly at high speeds.

This type of machinery finds uses in various industries. It is vital in processes that require consistent air supply. Despite its many advantages, the Roots blower can sometimes be noisy. Maintenance is crucial as well, as wear can impact performance. Understanding these dynamics can help optimize their use, sparking discussions about improvements and innovations in airflow technology. The balance between efficiency and practicality remains a pivotal topic.

| Parameter | Description | Typical Value |

|---|---|---|

| Airflow Rate | The amount of air the blower can move, typically measured in cubic feet per minute (CFM). | 50 - 5000 CFM |

| Pressure Range | The output pressure of the blower, usually measured in inches of water column (in WC). | 1 - 15 in WC |

| Power Consumption | The electrical power required to operate the blower, measured in horsepower (HP). | 1 - 100 HP |

| Efficiency | The ratio of useful output power to input power, expressed as a percentage. | 70% - 90% |

| Maintenance Frequency | How often the blower requires servicing to maintain optimal performance. | Every 3 to 6 months |

A Roots blower is a positive displacement machine. Its key components include rotors, housing, and an inlet/outlet system. The two rotors are the heart of this blower. They are shaped like lobes and rotate in sync. This design allows air to be moved efficiently. As one rotor turns, it creates a vacuum, drawing in air through the inlet.

The housing encapsulates the rotors. It keeps the system contained and ensures proper air flow. The gap between the rotors and housing is critical. If too wide, efficiency drops. If too narrow, friction increases, causing wear. Adequate lubrication is necessary to reduce wear and tear on components.

Various applications utilize Roots blowers. They can be found in wastewater treatment and pneumatic conveying systems. However, installation mistakes can lead to inefficiencies. For instance, improper alignment often creates vibration issues. Regular maintenance is essential to ensure optimal performance and longevity. Understanding these components helps in troubleshooting and improving the blower's function.

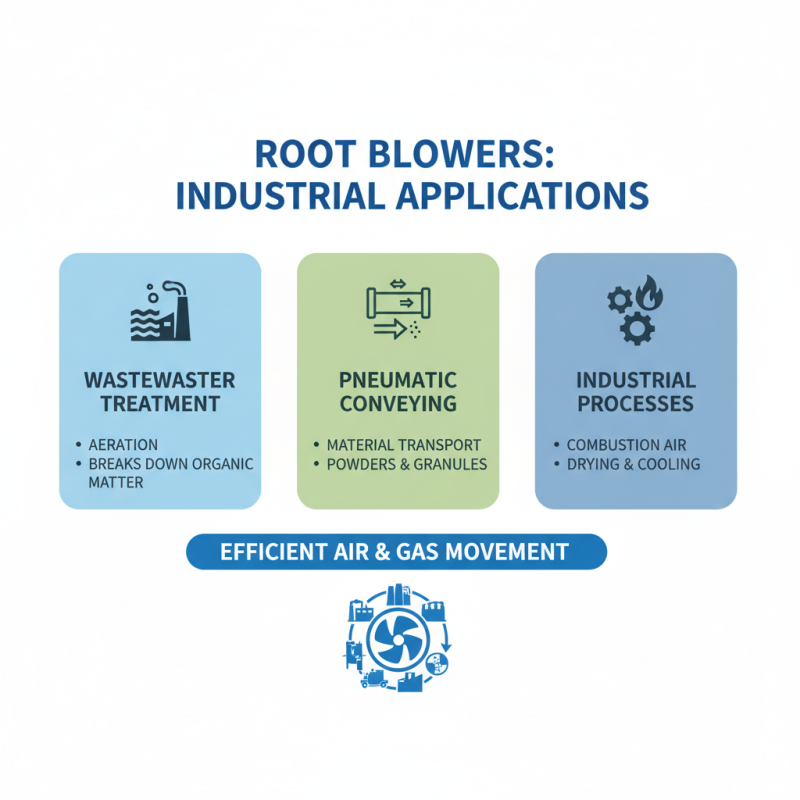

Roots blowers play a significant role in various industries. They are used for air and gas movement in many applications. One common use is in wastewater treatment. Here, roots blowers aerate the water. This process helps in breaking down organic matter.

Another key application is in pneumatic conveying systems. Roots blowers transport bulk materials, such as powders and granules, through pipes. They ensure a smooth flow of materials. In the food industry, they help in maintaining safe environments by moving air efficiently. Many factories depend on their reliable performance.

Tips for effective use: Regular maintenance is crucial. Check for wear and tear often. Inadequate maintenance can lead to costly downtime. Be mindful of potential energy consumption. Overloading can decrease efficiency, leading to failures. Always monitor operating conditions closely. Small changes can impact overall performance.

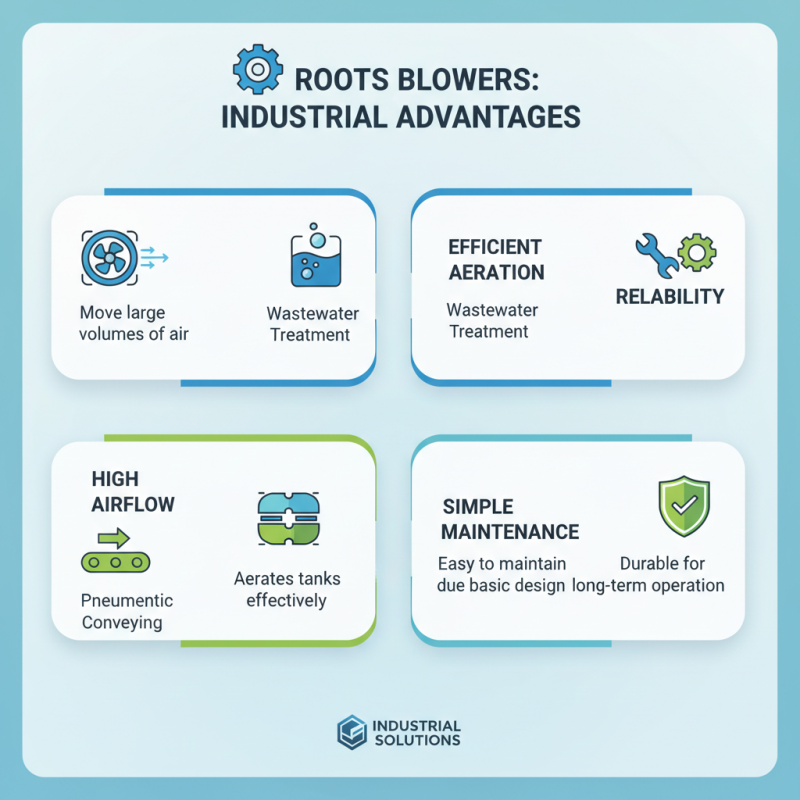

Roots blowers are popular tools in various industrial applications. They offer specific advantages. One major benefit is their ability to move large volumes of air efficiently. This makes them ideal for pneumatic conveying. In wastewater treatment, they help aerate tanks effectively. Their simple design allows for easy maintenance. Users often appreciate their reliability over long periods.

However, limitations exist. They can be quite noisy. This may require soundproofing measures in certain settings. Energy consumption is another issue. Compared to other types of blowers, roots blowers may use more power at lower efficiencies. Furthermore, they might not be suitable for all applications. Users need to consider pressure requirements carefully. In some cases, enhanced energy costs can outweigh the operational benefits. A thorough analysis is advisable before making a decision.