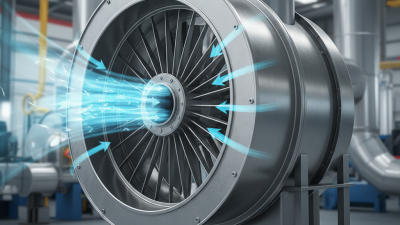

Centrifugal ventilation fans play a crucial role in modern air management systems. They enhance airflow efficiency in various settings. These fans use a unique design to move air in a controlled manner. Their structure allows for better pressure control and volume movement.

When selecting a centrifugal ventilation fan, considerations must include the application and environment. Factors like fan speed, noise level, and energy efficiency matter. For instance, industries may require robust fans to manage heavy airflow. Meanwhile, residential applications might prioritize quieter operations.

Reflecting on the use of these fans reveals challenges too. Not every fan suits every situation. Some may lack the needed power or efficiency. Understanding these limitations can guide smarter choices for optimal airflow solutions.

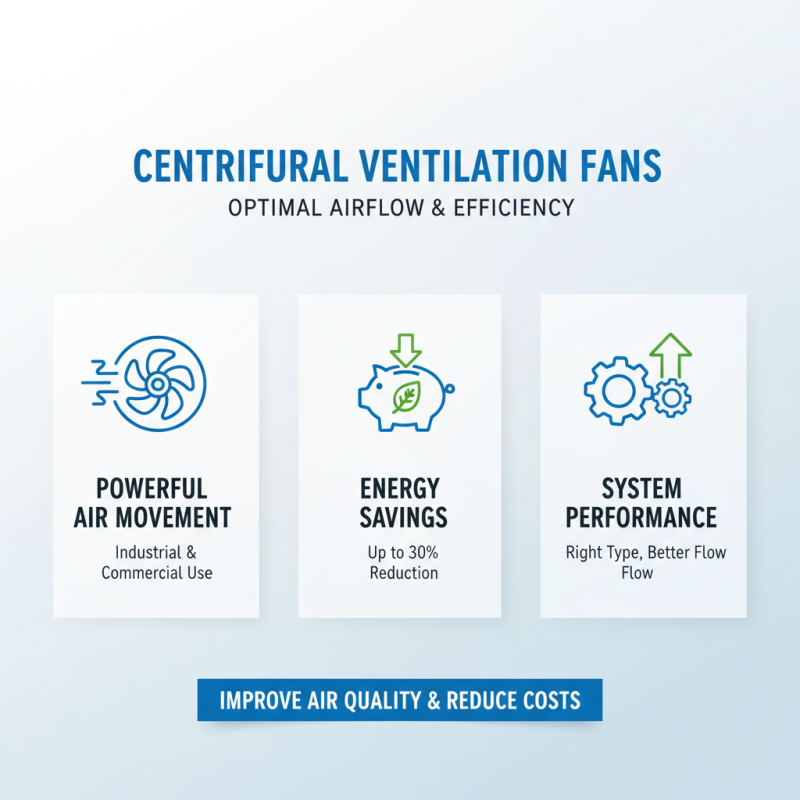

Centrifugal ventilation fans are vital for effective airflow in various applications. They deliver powerful air movement, making them ideal for industrial and commercial settings. Studies show these fans can reduce energy consumption by up to 30% when properly selected and maintained. The right fan type significantly influences airflow efficiency and system performance.

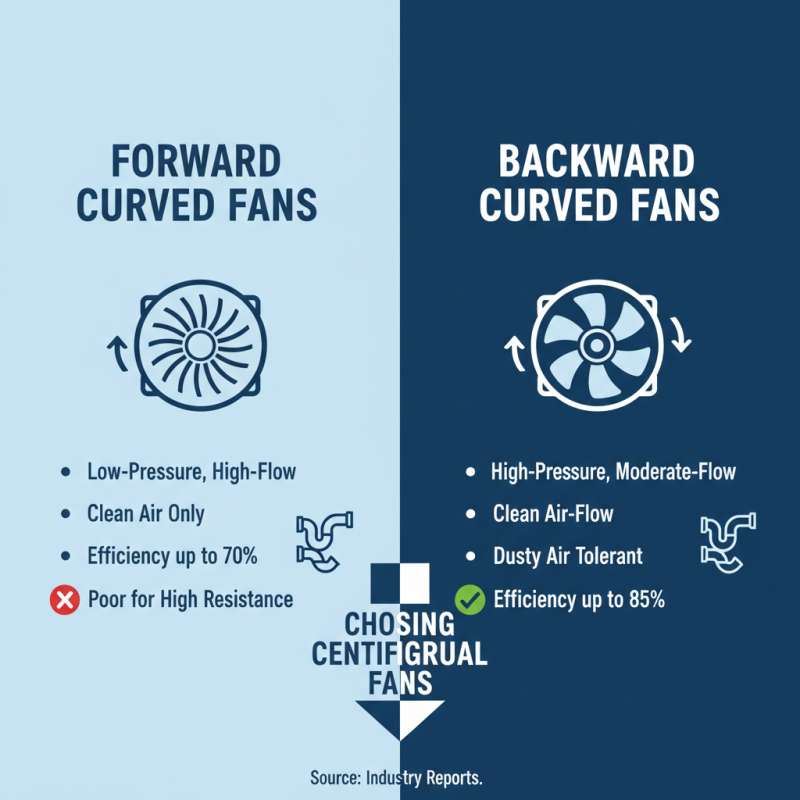

Common types include forward-curved and backward-inclined fans. Forward-curved fans excel in applications needing high airflow at low pressure. They are efficient but can be noisy. Backward-inclined fans, on the other hand, handle higher pressures better and operate quieter. Choosing the right type depends on specific airflow needs and space constraints.

**Tips:** Keep an eye on maintenance schedules. Regular cleaning can enhance performance significantly. Consider the noise level in workspaces to ensure comfort. Avoiding common mistakes, like installing fans in poorly designed ducts, can lead to wasted energy and decreased efficiency. Select fans based on precise data and application requirements. This will make a noticeable difference.

Understanding the efficiency ratings of centrifugal fans is crucial for optimizing airflow. These fans come in various designs, each offering unique benefits and drawbacks. Some models excel in high static pressure applications, while others are better suited for high-volume airflow requirements. Designers must consider specific needs when selecting a fan type.

Efficiency ratings often depend on the fan design and its operating conditions. For example, backward curved fans typically provide higher efficiency than forward curved models. However, they may not perform as well in certain environments. Factors like noise levels and space constraints also play vital roles in fan selection.

While high efficiency is important, there are trade-offs to consider. Some centrifugal fans require more powerful motors, which can lead to increased energy costs. Moreover, installation complexities can arise, leading to possible future issues. Evaluating these factors is imperative for making informed decisions in airflow solutions.

This chart illustrates the efficiency ratings of different types of centrifugal ventilation fans, providing insights into their airflow performance. The data represents the average efficiency ratings measured in CFM (Cubic Feet per Minute) against different fan types.

When assessing centrifugal ventilation fans, key performance metrics play a pivotal role. The airflow rate, measured in cubic feet per minute (CFM), is essential. A higher CFM indicates better air movement. According to industry reports, an efficient centrifugal fan typically provides a CFM range of 1,000 to 30,000, depending on application needs.

Pressure rise is another crucial factor. It measures how well a fan can overcome resistance in ducting or filters. Performance metrics reveal that a pressure rise of 5 to 10 inches of water column (in WC) is common. It indicates effectiveness in various installations. Noise level also affects fan selection. Quiet operation often falls below 85 dBA at maximum speed, enhancing user comfort in residential or commercial spaces.

Tips: Choose fans with adjustable speed options. Flexibility can significantly improve efficiency. Regular maintenance is vital too. Dust and debris can impair performance. Periodic checks can prevent issues down the line. Remember, testing fans in actual operating conditions often leads to better insights than theoretical calculations. Always compare your fan choices against your specific needs.

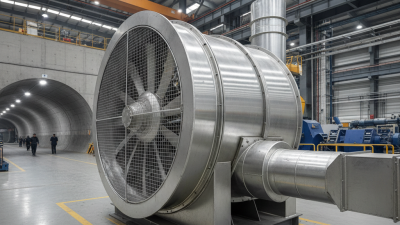

Centrifugal fans play a crucial role in both industrial and commercial environments. In manufacturing plants, these fans efficiently move air, enabling effective cooling processes. They help in maintaining optimal temperatures and reducing heat buildup in machinery. This enhances overall productivity. However, improper fan selection can lead to inadequate airflow.

In commercial settings, such as restaurants or warehouses, centrifugal fans assist with ventilating spaces. They help remove stale air and odors, promoting a healthier atmosphere. The fans also contribute to energy savings, as they can operate at varying speeds. But not all installations guarantee efficiency. Sometimes, the layout of air ducts can hinder airflow.

Maintenance is key for optimal performance. Dust accumulation can impede fan capabilities, making regular checks essential. Users often overlook this aspect, leading to subpar results. Many also underestimate the noise generated by fans, impacting work environments. Addressing these issues will improve both function and comfort.

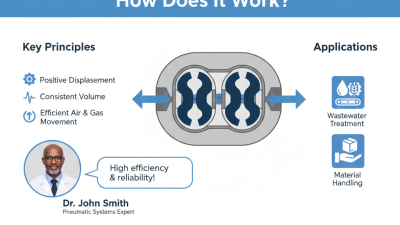

When choosing centrifugal ventilation fans, comparing the forward curved and backward curved types is essential. Forward curved fans operate efficiently in low-pressure applications. They are suitable for clean air environments. According to industry reports, they can achieve efficiency rates of up to 70%. However, their design makes them less effective for high-pressure systems. They often struggle against resistance, which can lead to higher operational costs.

On the other hand, backward curved fans excel in high-pressure conditions. They can handle larger volumes of air due to their blade design. These fans tend to have better energy efficiency, often exceeding 80%. Industry studies show that they also produce less noise, which is vital in commercial settings. However, their complexity can increase maintenance needs.

Tips: Consider the application before selecting a fan type. Think about energy efficiency and noise levels. Regular maintenance checks can help sustain performance over time. Choose based on specific needs, not just efficiency ratings.

Centrifugal ventilation fans are essential for ensuring efficient airflow solutions in various industrial and commercial settings. This article examines the different designs of centrifugal fans and their efficiency ratings, emphasizing key performance metrics that help in evaluating their effectiveness. It highlights the applications of these fans, including their roles in enhancing air quality and regulating temperature in diverse environments.

A comparative analysis of fan types, particularly forward curved versus backward curved designs, sheds light on their operational differences and efficiencies. Additionally, the article offers insights into energy consumption, providing strategies for optimizing centrifugal fan performance to achieve cost-effective and sustainable airflow solutions. Overall, understanding these elements is crucial for selecting the right centrifugal ventilation fan for specific needs.