An Overview of Centrifugal Fans

Core Components

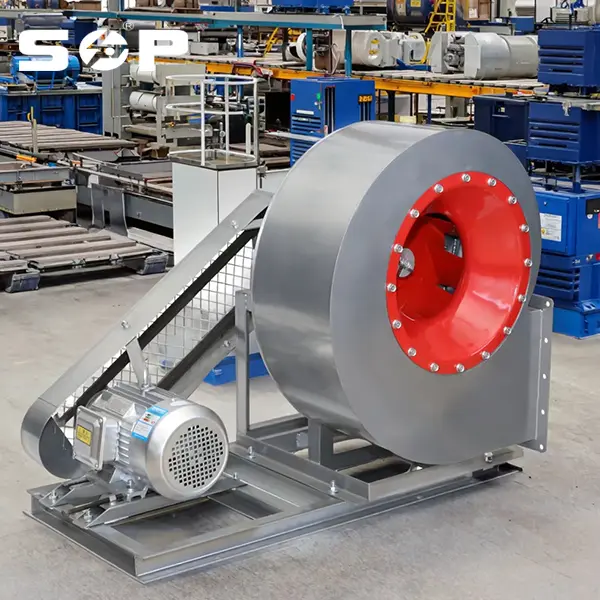

Centrifugal Fans consist of key working components that directly participate in gas transmission and auxiliary components that ensure stable operation, with each part performing its specific function.

1.Key Working Components

a.Impeller: Known as the "heart" of the centrifugal fan,comprises blades attached to a hub—forward-curved blades for small-volume low-pressure scenarios and backward-curved ones for high-pressure operations due to better efficiency.When the impeller rotates at a high speed, it pushes the gas to rotate together, and the gas gains energy under the action of centrifugal force.

b.The Housing(Casing):surrounds the impeller, guiding airflow and minimizing leakage, often shaped as a helical spiral for forward-curved impellers.Its outlet can be designed at different angles to facilitate connection with various pipelines.

c.Motor: It is the power source of the fan. Its power is matched with the air volume and pressure of the fan. It is connected to the main shaft through a transmission device to provide power for the rotation of the impeller.

d.Main Shaft: Made of high - strength steel, it connects the impeller and the motor. It is responsible for transmitting the torque of the motor to drive the impeller to rotate, and must withstand the centrifugal force and vibration generated during operation.

e.Air Inlet: It is a short circular or conical pipe located on the axial side of the impeller. It guides gas to enter the impeller smoothly and evenly. Some air inlets are designed in a streamlined shape to reduce air flow disturbance and resistance.

2.Auxiliary Components

a.Bearing Box: Equipped with bearings inside, it supports the main shaft, reduces friction during rotation and ensures the stable operation of the impeller.

b.Coupling or Belt Drive Device: The coupling is mostly used in large - scale fans for direct transmission with high efficiency. The belt drive is suitable for small and medium - sized fans, and the rotation speed can be adjusted by replacing the pulley.

Distinctive Features

- High Wind Pressure and Flexible Flow Regulation:

Centrifugal fans can generate much higher wind pressure than axial fans, which enables them to overcome the resistance of long pipelines and filters. Meanwhile, air flow can be adjusted in a wide range by changing rotation speed, adjusting angle of the guide vane and other methods to meet needs of different working conditions.

- Efficient and Stable Operation:

Near the designed operating point, centrifugal fans maintain high energy utilization efficiency, which helps reduce long - term energy consumption and operating costs. Their simple and precise structure leads to small vibration during operation. Especially the fans with forward - curved blades have obvious low - noise advantages, making them capable of continuous and stable operation for a long time.

3. Strong Adaptability: They can be customized according to different working environments. For example, high - temperature resistant materials are adopted for fans used in ceramic kilns, anti - corrosion materials are selected for those in sewage treatment plants, and explosion - proof motors are equipped for fans in petrochemical plants. In addition, they can be designed into modular structures for combined use.

Application Scenarios

- Industrial Field: In steel and cement plants, centrifugal fans are used to discharge high - temperature flue gas and dust. In the chemical and food processing industries, they are applied to transport powder materials or pressurize gas. Power plants rely on them to cool steam turbines and other large - scale equipment through forced air supply.

2. Construction and Civil Field: They are the core part of the central air - conditioning system in office buildings and commercial complexes, realizing air circulation and fresh air replacement. In underground garages and shopping malls, fire - proof and high - temperature resistant centrifugal fans can quickly exhaust smoke in case of fire. They are also used in hotel kitchens to discharge oil fume with matching purification devices.

3.Agricultural and Environmental Protection Field: In grain depots, they promote the drying of grains through forced ventilation to prevent mildew. In sewage treatment plants, they provide stable air for aeration tanks to assist microorganisms in decomposing pollutants. In large - scale farms, they regulate the air in pens, reducing temperature and removing odors.

4.Special Scenarios: Explosion - proof centrifugal fans are used in petrochemical plants to recover volatile oil and gas. Wear - resistant ones are applied in mines to discharge dust and harmful gases. High - temperature resistant models work stably in ceramic kilns to exhaust high - temperature waste gas.

In conclusion, centrifugal fans, with their excellent performance and wide adaptability, have become an important guarantee for the smooth operation of various industries. With the continuous advancement of technology, their efficiency will be further improved, and their application scenarios will be more extensive.