How to Use A Side Channel Air Blower for Material Conveying?

Side Channel Air Blowers, also known as regenerative blowers, offer a unique solution for efficient material conveying. Here’s a practical guide on how to leverage their capabilities effectively.

Understanding Side Channel Blowers

Side channel blowers operate by creating a high-speed airflow through a series of side channels. Unlike traditional blowers, they generate low-pressure but high-volume airflow, making them ideal for gentle material handling. Their design minimizes wear and tear, ensuring longevity even in demanding environments.

Step-by-Step Guide to Material Conveying

1. Assess Your Material Requirements

Before selecting a side channel blower, evaluate the material properties:

Density and size: Lightweight, granular materials like powders or small pellets are best suited.

Moisture content: Avoid overly wet materials, as they can clog the system.

Abrasiveness: Non-abrasive materials reduce wear on the blower’s components.

2. Choose the Right Blower Size

Match the blower’s airflow capacity to your material volume. A blower that’s too small will struggle to convey material efficiently, while an oversized blower may waste energy. Consult the manufacturer’s specifications for optimal performance.

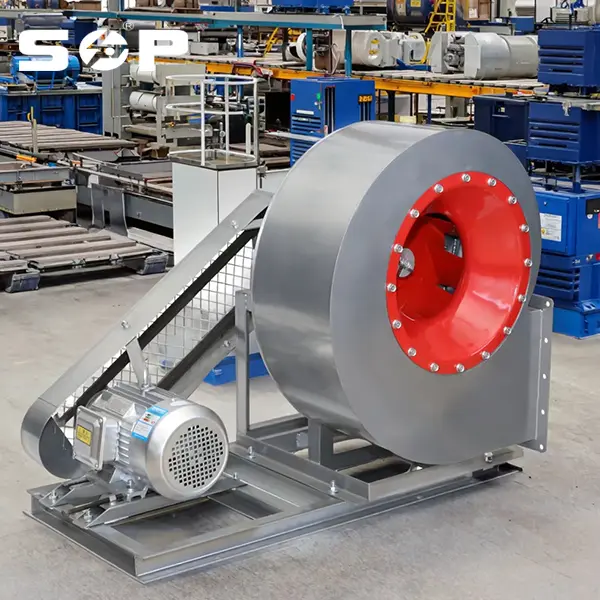

3. Install the Blower Correctly

Positioning: Place the blower close to the material source to minimize airflow loss.

Inlet and outlet: Ensure smooth transitions between the blower and conveying pipes to reduce turbulence.

Vibration isolation: Use mounts or dampeners to prevent vibrations from affecting material flow.

4. Optimize Airflow Control

Regulate pressure: Adjust the blower’s pressure settings based on material density. Higher pressure may be needed for dense materials.

Use control valves: Install valves at strategic points to fine-tune airflow and prevent material backups.

5. Maintain the Blower Regularly

Inspect filters: Clean or replace air filters to prevent dust buildup, which can reduce efficiency.

Check belts and bearings: Ensure they are properly lubricated and aligned to avoid mechanical failures.

Monitor performance: Keep an eye on airflow rates and pressure readings to detect issues early.

6. Troubleshoot Common Issues

Material jams: If material accumulates in the pipeline, check for blockages or adjust airflow settings.

Excessive noise: Unusual sounds may indicate misalignment or worn components.

Reduced efficiency: Dirty filters or clogged channels can impair performance—clean them promptly.

Benefits of Side Channel Blowers for Material Conveying

Energy efficiency: They consume less power compared to traditional blowers.

Low maintenance: Fewer moving parts mean fewer breakdowns.

Gentle handling: Ideal for delicate materials that could be damaged by high-pressure airflow.

Final Thoughts

Side channel air blowers are versatile tools for material conveying, but their effectiveness depends on proper selection, installation, and maintenance. By following these steps, you can optimize your material handling process and ensure smooth operations.