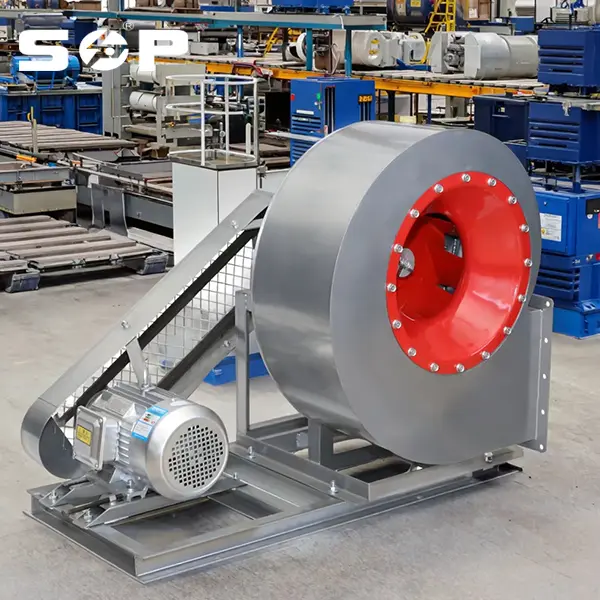

SOP Industrial Co., Ltd's High Pressure Blowers: Leading the Industry with Innovation and Efficiency

1. Core Technology: Innovation Driving High Efficiency

SOP's high-pressure blowers utilize dual-stage compression technology, which enhances air pressure by over 30% while reducing energy consumption by 15% through optimized impeller design and airflow channeling. The core components, made from aerospace-grade aluminum alloy, undergo precision CNC machining to ensure impeller dynamic balance accuracy of G2.5, effectively minimizing vibration and noise and extending equipment lifespan. Additionally, the company's independently developed intelligent frequency conversion control system allows for real-time speed adjustment based on operational conditions, enabling "on-demand air supply" and eliminating energy waste. For instance, in the ceramic industry's drying process, this technology enables annual energy savings of over 20,000 kWh per unit, facilitating green transformation for enterprises.

2. Application Scenarios: Meeting Diverse Industry Needs

SOP's high-pressure blowers, with their modular design, cater to a wide range of applications, excelling in environmental protection, chemical, and food processing sectors:

Environmental Protection: For wastewater treatment aeration, the blowers feature anti-corrosion coatings and sealed structures, ensuring continuous operation in high-humidity and corrosive environments. A large-scale wastewater treatment plant reported a 20% increase in aeration efficiency and a 40% reduction in maintenance costs after adopting SOP equipment.

Chemical Industry: Explosion-proof high-pressure blowers, certified by ATEX, are suitable for flammable and explosive environments. Their oil-free design prevents medium contamination, ensuring production safety.

Food Processing: Made from FDA-compliant food-grade materials, these blowers ensure clean air delivery, widely used in baking and packaging processes, helping enterprises meet HACCP certification requirements.

3. Service Advantages: Comprehensive Support Throughout the Lifecycle

SOP Industrial Co., Ltd has built an integrated "pre-sale, during-sale, after-sale" service system:

Customized Solutions: The engineering team conducts on-site assessments to provide tailored recommendations based on client parameters (e.g., air volume, pressure, temperature), avoiding "oversizing" issues.

Rapid Response Mechanism: With 12 service centers nationwide, the company guarantees on-site arrival within 24 hours, equipped with professional diagnostic tools for precise fault detection and efficient repair.

Extended Warranty Value-added Services: Offering a 3-year extended warranty, SOP also introduces a "trade-in" program, helping clients reduce equipment upgrade costs.

4. Client Testimonials:

A renowned building materials company stated: "SOP's high-pressure blowers have operated stably in a 120℃ high-temperature environment for three years without performance degradation, significantly exceeding industry standards." An electronics manufacturer added: "The intelligent control system reduced production line energy consumption by 18%, saving over 500,000 yuan annually in electricity costs." These testimonials validate SOP's outstanding performance in reliability and energy efficiency.

Conclusion

SOP Industrial Co., Ltd, rooted in technology and committed to service, continues to drive innovation in the high-pressure blower industry. Whether you're facing harsh operational conditions or energy-saving demands, SOP offers efficient and reliable solutions. Choosing SOP means not just selecting a blower but also partnering with a long-term, stable productivity ally. Contact SOP's team today to embark on your power upgrade journey!