What Does A Frequency Converter Do?

Breaking it Down: What is a Frequency Converter?

At its core, a frequency converter is a device that changes the frequency of electrical power supplied to a motor or other equipment. Electrical systems typically work on fixed frequencies—like 50 Hz or 60 Hz—depending on the region. However, various applications require specific speeds or performance levels that don’t align with those standard frequencies. This is where the frequency converter comes into play.

The Science Behind It

Frequency converters convert incoming AC (Alternating Current) power to a desired frequency by essentially modifying both the voltage and the frequency of the electrical signal. They can be classified mainly into two types:

Static Frequency Converters: These use a system of rectifiers and inverters to convert the input frequency into the desired output. They are suitable for applications where the load is constant.

Dynamic Frequency Converters: These are typically more complex and can handle variable loads. They may involve rotating machinery and are often used in large-scale operations, such as industrial processes.

Why Use a Frequency Converter?

So, why exactly do we need frequency converters? Here are a few key reasons:

Speed Control: Motors that power conveyors, fans, pumps, and other machinery often require speed adjustments based on operational needs. Using a frequency converter allows for smooth control of motor speed, which not only enhances efficiency but also extends the life of the equipment.

Energy Savings: Properly matched frequency converters can lead to impressive energy efficiency. By adjusting the frequency to match the required load, you reduce the energy waste associated with running motors at constant speeds. This can translate to significant cost savings over time.

Compatibility Across Regions: Different parts of the world use different frequencies. For instance, North America uses 60 Hz, while many other regions use 50 Hz. Frequency converters enable equipment designed for one region to operate in another without issue, making them essential for global manufacturers.

Power Quality Improvement: Some frequency converters provide filtering capabilities, helping to reduce harmonics and improve overall power quality. This is critical for sensitive electronic equipment that could otherwise be disrupted by poor power quality.

Real-World Applications

You may not realize it, but frequency converters are ubiquitous in our daily lives. Here are some common applications:

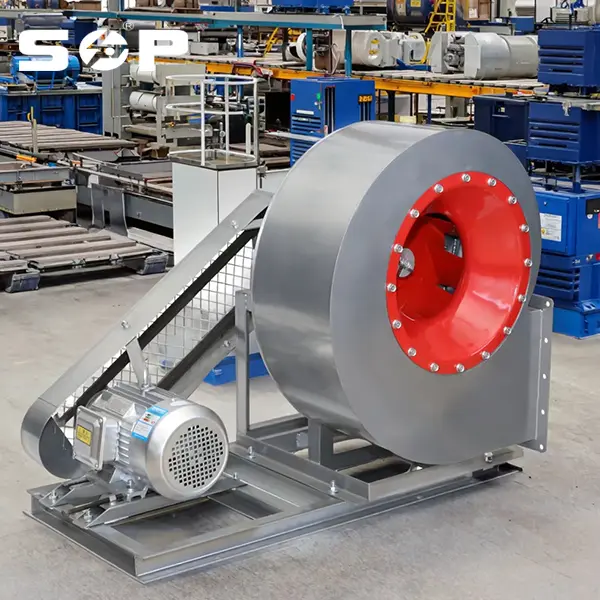

Industrial Automation: Many manufacturing processes rely on frequency converters to control motors used in machinery, conveyor belts, and robotic arms to optimize performance.

HVAC Systems: Heating, ventilation, and air conditioning systems often use frequency converters to adjust fan speeds and pump outputs based on demand, improving energy efficiency.

Renewable Energy: Wind and solar power systems frequently use frequency converters to convert variable inputs into a stable output suitable for integration into the electrical grid.

Elevators and Escalators: These systems utilize frequency converters to ensure smooth starts and stops, enhancing the safety and comfort of passengers.

Final Thoughts

Whether you know it or not, frequency converters are an essential part of modern electrical systems. They enable better control, efficiency, and functionality across a wide range of applications. As industries continue to push for smarter and cleaner technology, the significance of frequency converters is only set to grow. So next time you’re riding an elevator or watching a factory operate, just remember: there’s a good chance a frequency converter is making it all run smoothly!